Notizie sulle nostre innovazioni, eventi, relazioni con operatori locali e globali e con la nostra comunità, pubblicate su una varietà di riviste internazionali.

International Confectionery

October 2022

Integrated automation with Emiliano Leonardi (Head of Automation Design with CEPI)

CEPI is a provider of fully customized bulk-handling systems, which includes the integrated automation of all operations, including multiple PLC solutions with HMI for the complete management of production and Tracking System software providing process control, warehouse management and full traceability. Hardware and software design is done completely in-house. With a team of 24 programmers working on automation and software design, we are able to provide technical and human continuity through the development of a project that can become very specific and complex.

The automatization of the dosing system governs all operations from the loading of storing stations to conveyance and dosing, including all processes such as fermentation and control on parameters such as temperature, pH, atmosphere, which is crucial in preserving the properties of ingredients such as flour or fats. The recipe is managed exactly in the way indicated by the customer: we only provide accurate automation and the most suitable dosing technology, as well as our expertise in how to optimize the management of various ingredients. We do not overturn their product or their process.

In CEPI, it is our mission to provide a turn-key solutions, that is, solutions that make the user independent. In practice, in our systems the processes are covered from storing to dosing, and we support any materials and processes the user wishes to include due to a very diversified technological offer. We already possess internally all expertise needed to design, build and commission the system, and finally we provide the automation and all the data related to the operations run by the system.

Turnkey systems

Designing a dosing system is a complex process that requires a close analysis of the manufacturer’s processes and detailed information that goes beyond the purely technical. Our process involves all departments from werehouse, to production, technical, purchasing and marketing, to include projection of future productions and create a system that will easily accomodate future developments and expansions.

Our systems are based in long term thinking in order to create the most flexibile solution for each food manufacturer and not preclude any new path they may take in the future. As such, they are very easy to revamp, which contributes to the already high circularity of our product, where equipment have a long life and are mainly built in stainless steel. As well as this, we guarantee continuity with a stable PLC based system that is very standardized and adaptable, therefore ready to follow all changes and future additions. Our automations are also designed to optimize all processes, leading to the minimization of energy and material consumption.

The automation system is development in parallel to the mechanical one. It’s very scalable and customizable, specific down to the single utility. We do not offer pre-ready packages as it is our firm belief that food manufacturers should adapt to our solutions but rather the opposite. We automate through a recipe that includes every technological step of production, including all dosing and mixing phases, their order and where they should happen.

This detailed study translates into a system that ensures not only repeatability and accuracy of recipe but also traceability of all materials and processes, higher efficiency and production volumes, reduced consumptions and pollutions, improved working conditions and less human error as well as enhanced communication with other software and ERP. Our systems make productions more hygienic, with total separation between production and warehouse and optimize space in both areas.

Scalable and customizable automation: what does it mean?

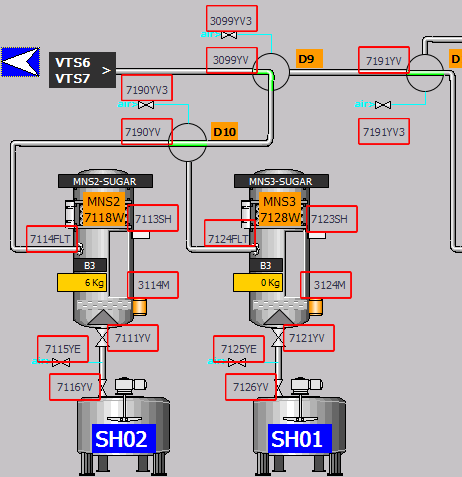

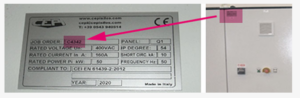

We provide multiple PLC solutions. Our customized 4-15’’ operator panels can be developed on Siemens or Allen Bradley platforms, and handle recipe creation and management, ingredient and hopper parametrization, synoptic overview with real time status and maintenance of utilities with manual command, loading of silos and other stations, as well as any other functions like washing and climatization. Weighing control in real time is provided for all our storing and dosing stations, along with the management of all other variables involved such as temperature and pH.

All our dosing systems are built on a recipe matrix with automation modules which includes commands regarding weight, temperature, number of batches and production cycles for each step. Steps include both dosing and unloading of ingredients. This kind of automation provides a recipe that is adaptable to each production and can be written in the way that is most suitable to its technological and logistic requirements.

The recipe is written on a table which allows to select fully parametrized ingredients for each chronological step, and to establish the quantity that will be dosed, the temperature of the dosing and the duration. The number of cycles and batches can also be included, as well as unloading steps for each ingredient. A congruence check is performed on each step: that the product is within the established range, that each product comes with an unloading step and so on.

Planning the dosing method

Starting with the raw materials involved in the production, we first analyize each ingredient’s technological properties and their monthly and yearly consumptions, to establish their criticalities, advantages and if they allow optimizatios. We use this information to make decisions regarding the dosing method, such as that best matches the ingredient, the quantities that should be dosed in each batch and the overall production volume.

The set-up recommendations we share with our customers depend on the selected dosing method, the recipe itself, the type of ingredient (powder or liquid), the relevance of the ingredient (quantity and frequency of dosing).

Continuous dosing is selected when the downstream technological process requires it as the material flow itself is continuous and stations are not emptied and the filled discreetly. This goes for pasta lines, for micro ingredients such as additions to flour that are dosed through screws or rotary valves, for crystal sugar mills, or situations with a mill downstream of the flour or a minor addition must be made during pneumatic conveyance.

Batch dosing is the most common and applies to the majority of hoppers: addition or subtraction weighed hoppers, flow meters and micro ingredients hoppers. Of course large and small quantities require different mechanical solutions, and we provide stations for micro, medium and macro storage and dosage depending on the quantity and frequency of dosing.

Depending on the type of production, a single or multiple hoppers will be selected. For bakery lines we often recommend a single hopper for sugar and flour, while biscuits and similar products require the separation of ingredients such as powders, water, liquids like oil or yeast, and various micro inclusions on separate hoppers and flow meters, as the ingredients have different requirements, mixing times and separation allows hoppers to work in parallel and optimize production times.

Processes that require successive unloading and mixing of separate ingredients will also require multiple hoppers, as well as rework systems where a hopper is necessary to dose the recovered powdered or liquid product.

Tracking the flow of materials

Our software provides process control, warehouse management and full traceability with digitalization of all material movements. Our customers receive a complete picture of the production process in real time: we provide them with a history of storing and dosing operations, consumption statistics, batch report and related deviations, stock visualization and dynamic graphics illustrating all trends. Ingredients are monitored starting from the moment they enter the warehouse, carrying a virtual label through all production which adds new information every time an operation is performed on the ingredient.

All our data can be easily integrated with global ERP or MES to achieve organization-wide traceability. Our process control software is open, and the information is immediately available for the user, who can use it however they decide. Because we develop our software completely in-house, we are not bound to any third party and therefore our customers are not either.

On top of this, the data can be used in as many ways as the customer wants. They can quickly carry out mass production balances, check consumptions, generate information for Quality Control and Purchases, create projections of future productions and optimize the current process. Data on the tolerance and queue of dosing processes can be used to check the status of the equipment and determine if it requires maintenance.

Ingredients are monitored starting from the loading moment:

- through our software when they enter the warehouse, when a first digitalization with codebar happens attaching a virtual label to the lot with product loading time, name, quantity, expiration, packing slip, supplier, and anything else the manufacturer deems necessary. This ingredient is now available for dosing in production, and the information will be carried through the dosing process, while also being made available for any other traceability software operating in the factory

- a second digitalization with codebar happens when the lot is loaded into dosing. All the information attached to the lot’s virtual label is carried through the production, now including new info such as loaded weight, loaded units (bags, bowls and such) and loading time. We also perform a congruence check to verify that each ingredient is transferred into the appropriate silo

- our software receives a history of production operations from our own touch panels, which manage such operations on the lines, making information available for all dosing and unloading operations of each ingredient lot, including all stations and conveying systems it moves through

- All this information is stored on SQL server and can be exchanged

Latest developments

As mentioned, the recipe management we provide is very integrated and includes all technological processes in a single recipe, which means all dosing and mixing steps (inclusive of different mixing speeds, mixing in changing locations, cooling, creaming and so on.) Not only that but we manage processes such as the washing of the dosing systems (for example through Clean In Place), which means we can provide a record of the batches, that is full traceability.

Recently, we have developed a very complex automation for an Italian biscuits producer whose process includes more than thirty hoppers for each line for more than 20 ingredients. All of this is managed by a single integrated recipe with more than 60 ingredients.

Another development regards the complete bidirectionality of data between management and production, with easy options to export all data histories required by ERPs and also manage production orders directly, becoming an interface between ERP and production. All production programs can be run remotely.

International Bakery

September 2022

Sourdough: fragrant products with long shelf life

Sourdough is a mixture of water and flour fermented by a set of microorganisms including lactic and acid bacteria and yeast, which are naturally found in the flour. Sourdough bread is tastier, more fragrant and healthier. Easy to digest and with a high nutritional value, it achieves a long-shelf life without preservatives, meeting the increasing demand for food manufactured through processes that preserve the natural properties of its ingredients.

Rye, wheat and multigrain breads but also pizza, focacce, brioches and crackers: in the last two decades, the defining factor in bakery manufacture has been the rediscovery of sourdough, and the development of technologies that make artisan quality possible on an industrial level.

Why is sourdough so good?

Sourdough bread has many benefits: a big one being the long shelf life, as sourdough is more acidic and less prone to develop degenerative bacteria and moulds, so starch retrogradation and staling are delayed.

Sourdough bread is also easy to digest as leavening is longer: starches are metabolized and broken by the microorganisms in the dough, making it easier for the body to process them. With sourdough, there is no need to use additives and improvers to break the starch and to aid flour tightness during the process.

On top of this, sourdough increases the hydration of proteins and creates a more uniform sponginess, as well as giving the finished product better organoleptic characteristics and a more complex aromatic profile. It develops aromatic aldehydes and adds a sour note, improving taste and fragrance.

History: from brewer’s yeast to sourdough

For the longest time, sourdough fermentation was the domain of artisan manufacturing. It was a highly empirical method that relied on the style of each individual producer, since there was no exact knowledge of the bacteria in the sourdough. Leavening the bread through the brewer’s yeast was the industry standard, but the final product saw a loss in fragrance and taste, as well as being harder to digest.

The identification of the bacteria and micro-organisms in the sourdough made it possible to create an easily repeatable recipe. With the evolution of the technology controlling physical parameters such as times, temperatures and pH, finally sourdough production became possible on an industrial scale for all the diverse fermentation processes – the black rye bread common in the Northern and Eastern parts of Europe relies on a more acid dough, while the white bread from the South based on soft wheat flour or semolina has a less acid note but a wider bouquet.

CEPI’s technology

CEPI provides fermenters and bread re-work dissolvers for sourdough (as well as pre-dough and polish). Our technology has been developed to combine natural processing and competitiveness: with a deep knowledge of the materials involved and of all aspects of the process, we offer flexible solutions that deliver precision and full control of all processes, as well as standardization and repeatability of procedures.

Modular and suitable for small, medium and big production volumes, our systems allow food manufacturers to produce healthy and aromatic products while saving space, manpower, additives and yeast. The technology fully preserves the characteristics of the raw materials and meets the highest standards of hygienic production.

We provide fully integrated automation with PLC control, with a flexible management that allows for both automatic and manual options for all operations.

International Confectionery

September 2022

The new headquarters

Almost forty years since its foundation and with an exceptional near 90% growth in the last decade, this early June CEPI inaugurated its new headquarters. CEPI’s new home has been a much much celebrated, much needed milestone for this Italian company that since 1985 has been designing, manufacturing and commissioning turn-key bulk-handling systems for food manufacturers all over the world.

The new facility tripled our productive area to a total of 15.000 square meters, with a 13.000 square meters factory space and the rest dedicated to offices. CEPI designed their new home according to the principles of safety and sustainability: they wanted it to be beautiful, but most of all, green and safe for all their employees. The new headquarters are powered and heated by renewable energy, including a 430 kw/h solar system, radiant floor heating, total heat recovery, recovery of rainwater for irrigation, refills for electric cars, high efficiency heat pumps, increased insulation and high brightness shed. They are fitted with microfiltration against fine dust in the air, welding gas distribution system, lighter-weight roof and swinging hooks.

But this space also reflects CEPI’s desire to guarantee that their customers are provided with a product that is exceptional in every respect, including heightened efficiency in production and a continuous investment in offering personalized, innovative solutions.

The layout of the new factory has been built through a detailed study of productivity and goods flows. Production is more centralized and rational, thanks not only to the added space but the optimization of all processes and waste reduction. Other important additions include automatic vertical warehouse, customs approved place, dedicated loading area, silo washing department, and a large expansion to the tall areas, which are up to 16 mt in height, for the construction of outdoor stainless-steel silos.

The new headquarters include a 240 square meters testing and prototyping room fitted with metrology room, a testament to their dedication to research aimed at creating a virtuous circle in their research. They will be able to perform more tests for their customers and provide them with more food technology assistance and assistance in the developments of their recipes.

CEPI always say that their product is the installation in all its interacting parts, and their service is costumization. The new testing room will be instrumental in ensuring the delivery of a fine-tuned, turn-key product that matches the materials of our costumers and optimizes their specific process. Their motto is: if your process needs it, we can do it. If we can’t do it yet, we will develop it, just for you. This is the vision that drove CEPI’s growth since its beginnings, enabling them to build around 10.000 installations all over the world with the most important operators in various food markets: from bakery, to confectionery, pasta, cereals, dairy, beverage, functional and baby food but also non food industries such as the pharmaceutical, chemical and paper industries.

With the new testing room, CEPI plans to create system wide prototypes, testing an increasingly wider range of materials – not only will CEPI able to test and develop new technologies, but customers will be able to access their systems and perform dosing and conveyance tests directly on their own materials.

This is especially crucial for processes such as microdosing and blending, which especially require precision and reliability. The dosing of minor ingredients often includes new food products or mixes, and the impact of equipment on their characteristic is unknown, requiring tests in controlled conditions. This is the case of mixes for functional or nutraceuticals foods with or without gluten, or resins and pigments in the chemical sector. In the confectionery sector, it is important to test any product with a high fat percentage such as whole milk and powder butter.

CEPI is going to make a number of systems similarly available for tests: their cold dosing system in paste form of fat, margarine and butter with its total control on temperature, and their system for the production, storing and dosing of invert sugar as well as a complete pneumatic conveyance system.

Heart of technology

After the past two years of restrictions, CEPI has been very happy to welcome old and new friends in their new home. Visits has been continuous and it has been a huge pleasure to meet face to face and show people their working method. CEPI deeply believes in establishing a very personal rapport with customers, requiring face to face interaction whenever possible, as shown by their immediate return to trade shows around the five continents. They accompany the food manufacturer through every stage of the process, from the initial analysis of product and process, to engineering and control, the direct manufacture of all equipment, logistics, commissioning and service.

Still, thanks to a flexible and already very digitalized working model, CEPI was able to keep operations running constantly even at the height of the COVID pandemic. A large percentage of their processes can be run remotely, including commissioning, assistance, and training. Many of their installations have been assembled remotely, and we can count on a worldwide network of local partners, which has further expanded and perfected its coordination in the wake of COVID. It’s thanks to these assets and the relentless efforts from everyone in our teams that our production and turnover have stayed stable around 28M since 2019.

The current situation presents many challenges, but they are confident in their ability to push through and grow, continuously offering a competitive product without ever backing down from our commitment to our people and territory.

The choices they are making are varied and all geared to strengthening their successful model: exploring new food markets and developing technologies aimed at their needs, big investments in research, machinery and training in order to offer an even more customized and automated product with solid food technology assistance for each project, growing their presence in various areas around the world with teams food technology in their headquarters, which will reproduce locally the levels of dynamism and skillful reliability customers have come to expect from CEPI.

CEPI provides an installation that includes the automation, and important innovations are happening in our process control system and operator panels as well, with further integration between the two systems and customizations including a powered production management up to 32 scales per each production line.

We are solidifying our sustainability processes, which includes in great part simply the narration and further certification of choices and actions we have implemented since our inception. On top of a very big commitment to ecological sustainability (which includes high circularity, the long life of their equipment and making it their mission to reduce their energy and material consumptions whenever possible), CEPI has since their inception practiced the principle of giving back: that is, that the people and communities they work with need to benefit from it. This has translated into a rich welfare program for our employees and their families and a concrete effort to leave a positive trace in the communities and territories we work with by not only directing supporting its most vulnerable groups but through the creation of many training and work placement opportunities with other local no profit organizations as well as collaborations with schools and university.

Bulk-handling: history and future of turnkey

Bulk-handling is not just about silos: CEPI designs their dosing system through a close analysis of the manufacturer’s processes and detailed information that goes beyond the purely technical and involves all departments from warehouse to marketing. Each of CEPI’s automation systems is fully customized to match analysis of raw materials, site evaluation, environment and consumptions, and designed through a comprehensive study of the manufacturer’s processes. CEPI has refined this process to perfection, building systems that fit the diverse needs of each process and will easily accommodate future expansions, ensuring a long life cycle to all of their equipment.

A turn-key system is a system that manages all processes from storage to dosing. Because CEPI is able to do this for all materials, and additionally to track all ingredients and provide the data, we are able to offer an integrated and fully traceable system that enables food industry operators to always have production under control. They build around 300 customised installations every year, focusing on the specificity and diversity of each installation and adapting or developing technologies according to their needs.

CEPI’s offer includes multiple indoor and outdoor storing options in stainless steel or antistatic fabric, minisilos and dumping stations for medium production volumes and broad spectrum stations for the storing and accurate dosing of micro ingredients. Materials are moved by clean and efficient conveyance systems designed to minimize energetic impact. Dosing can be continuous or batch, positive, by loss of weight, by volume or by weight, in modular hoppers for powders and tanks for liquids. The 3 in 1 station weighs the ingredient, separates air from product during pneumatic transport and comes with vertical blender for the production of premix. Other applications include flour cooling, fermentation, sugar mills, invert sugar technology, salt solution systems, fat and liquid tanks, fat cold metering, bread and biscuit rework systems including liquid rework of sandwich biscuits, and CIP washing system for a complete hygienization of tanks and pipes.

CEPI provides a turn-key system that includes fully integrated automation, with production management through touch panels and software for full traceability and warehouse management. Hardware and software design is done completely in-house. With vaste food technology expertise, all our technologies are developed factoring the preservation of flavour and ingredient properties, with automation ensuring repeatability and precision of the recipe. Each system is designed through a comprehensive study manufacturer’s processes that includes all operations from warehouse to marketing, and customized to match analysis of raw materials, site evaluation, environment and consumptions.

CEPI was founded in 1985, on the initiative of Pierdomenico Ceccarelli and Giuseppe Milanesi, who were later joined by Marino Montalti and Giancarlo Riccardi, all originally from the Forlì Apennines. Constantly adapting itself to its changing economical and cultural landscape and deeply attached to its territory, CEPI continues to grow under the banner of its founding values: prosperity and possibility for our community, attention to people and the planet, to our partners and to peace, which is especially crucial in our times and which CEPI, which talks and works daily with people all over the world, sees as the basis for fair and widespread economic development.

Rassegna stampa

Giugno 2022

CEPI: la nostra nuova casa

CEPI: la nostra nuova casa

Grazie a tutte le riviste del nostro territorio che hanno parlato dell’inaugurazione della nostra nuova sede e a Radio Bruno, che ha intervistato l’Amministratore Delegato Sandra Ceccarelli.

CEPI è nata nel 1985, per iniziativa di Pierdomenico Ceccarelli insieme a Giuseppe Milanesi, a cui poi si unirono anche Marino Montalti e Giancarlo Riccardi, tutti originari dell’Appennino forlivese. Dopo quasi quarant’anni, abbiamo inaugurato la nostra nuova casa.

Ci siamo trasferiti nel nuovo quartier generale l’autunno scorso, ma abbiamo atteso che le condizioni generali migliorassero per condividere questo piccolo, grande momento di festa insieme a dipendenti, collaboratori e a chi ci ha sostenuto fino al raggiungimento di questo nuovo traguardo.

Sono intervenuti il Vescovo di Forlì-Bertinoro, Mons. Livio Corazza, il Vicesindaco di Forlì, Daniele Mezzacapo, e l’Assessore alle Politiche per l’impresa, Paola Casara.

CEPI continua a crescere all’insegna dei suoi valori fondanti: Possibilità per il territorio, attenzione alle Persone, al Pianeta, ai nostri Partner e, soprattutto in un contesto come quello odierno, alla Pace, un tema a cui CEPI, che quotidianamente dialoga con il mondo, guarda con la convinzione che sia la base per uno sviluppo economico equo e diffuso.

International Confectionery

October 2021

Providing a turnkey solution

Providing a turnkey solution

Riccardo Satta is a food technologist with two decades of food industry experience both in R&D and in the manufacture of bulk-handling installations. In CEPI, he handles R&D supporting the engineering department in finding the most suitable technical solutions for materials and food products, as well as supporting customers with the development of their installations. Within the Sales Team, he is the Area Manager for Africa. Here, he speaks with International Confectionery about turnkey solutions and how CEPI have developed and grown in recent times.

Cepi is in the process of opening its doors to a new HQ. Can you tell us more about this and how it will boost production and innovation?

After the exceptional growth in the past decade, we have built a new facility that tripled our productive area to a total of 15.000 m2, with a 13.000 m2 factory space and the rest dedicated to offices. The new headquarters include a 240 m2 testing and prototyping room fitted with metrology room, which is a testament to our dedication to research. We will be able to perform more tests and provide more food technology assistance to our customers.

Our aim with is to create a virtuous circle in our research. With a dedicated space one idea will even more quickly lead to the other, in line with a vision that has always been centered around technology and customization. Our systems are turn-key, which has a deep meaning to us. From technological diversification to personalized innovation, from bulk-handling equipment to data, we aim to provide systems that can be managed in total independence once commissioning is done.

How will you enhance personalisation and support for your customers in this new HQ?

Our customers will be able to perform dosing and conveyance tests directly on their own materials. We also plan to develop system wide prototypes. With prototypes always available, we will be able to test an increasingly wider range of materials. The dosing of minor ingredients often includes new food products or mixes, and the impact of equipment on their characteristic is unknown, requiring tests in controlled conditions. This is the case of mixes for functional or nutraceuticals foods with or without gluten, or resins and pigments in the chemical sector. In the confectionery sector, it is important to test any product with a high fat percentage such as whole milk and powder butter.

Personalization and innovation are tightly connected to each other for us. Our research is often driven by the specific needs each food manufacturer brings to us: our latest dosing station 3in1 (which combines weighing, blending and direct loading on the pneumatic line) has been developed in response to a customer’s need to optimize his productive area.

We are able to provide turn-key systems because of our technological range, which is not limited to manufacturing equipment but extends to the development of our data management systems.

How does the turnkey quality of CEPI’s installations include machinery but also data?

A turn-key system is a system that manages all processes from storage to dosing. Because CEPI is able to do this for all materials, and additionally to track all ingredients and provide the data, we are able to offer an integrated and fully traceable system that enables food industry operators to always have production under control.

Our Tracking System software provides process control, warehouse management and full traceability with digitalization of all material movements. Our customers receive a complete picture of the production process in real time: we provide them with a history of storing and dosing operations, consumption statistics, batch report and related deviations, stock visualization and dynamic graphics illustrating all trends. Ingredients are monitored starting from the moment they enter the warehouse, carrying a virtual label through all production which adds new information every time an operation is performed on the ingredient.

All our data can be easily integrated with global ERP or MES to achieve organization-wide traceability. Our process control software is open, and the information is immediately available for the user, who can use it however they decide. Because we develop our software completely in-house, we are not bound to any third party and therefore our customers are not either.

Why is data management important and in what ways can customer use the data provided?

Gathering, storing and making data on the materials available is crucial to a healthy process. Firstly, it allows traceability and ensures food security, by knowing which ingredient lot from warehouse was dosed into each final unit. Secondly, process data makes it possible to verify the efficiency of a system.

On top of this, the data can be used in as many ways as the customer wants. They can quickly carry out mass production balances, check consumptions, generate information for Quality Control and Purchases, create projections of future productions and optimize the current process. Data on the tolerance and queue of dosing processes can be used to check the status of the equipment and determine if it requires maintenance.

We are also working on ways to generate more process data, including a historicization of alarms that can aid in planning personalized maintenance. We are also developing ways to historicize energy consumptions.

For you, what qualifies as a ‘turnkey solution’?

Earlier I mentioned that a turn-key solution in our sector is one that manages all processes from storage to dosing. This is true, but this aspect is a consequence of the main quality of a turn-key solution, which is to make the user completely independent.

What makes a system completely independent? As I said, the process needs to be covered from beginning to end, which in our case means storing to dosing. The builder’s technological offer should be very diversified in order to support any materials and processes the user wishes to include, without the need to involve another supplier. Then, the builder needs to possess all expertise needed to design, build and commission the system.

This is our working method. CEPI has been founded and has grown around the very idea of being turn-key provider.

Why do you feel this kind of solution has value for your customer?

The customer is using a tailor-made installation that has been designed to meet their needs. We automatize and optimize their production, enabling their growth in a modular way without ever overturning their process. This means that a food manufacturer won’t have to adapt to a pre-made solution but rather the opposite happens.

Aside from the obvious considerations over reduced costs, working with a single provider also means interfacing with only one interlocutor, who will have complete knowledge of their system, and who has designed, built and commissioned it.

Do you believe every installation requires an open dialogue with customers and crew?

Every installation is unique and has its own story. This is the heart of turn-key work: the dialogue and information exchange with the customer is always open, which creates growing opportunities for both of us. If the customer chooses it, CEPI can enter more deeply in their process and create an optimization proposal based on our experience. This is the case of a recent collaboration where we designed a more efficient dosing solution to include fruit and chocolate in a biscuit line, all without altering the authentic flavor of their product.

What challenges do raw materials pose and why is a turnkey solution integral to manage these?

A system is only turn-key if it overlooks all aspects of the production context it operates in. In our systems, the materials are managed and traced from the beginning to the end of the process. This not only allows extreme precision in the set-up of each operation (with management of aspects such as temperature and atmosphere), but also, we can constantly adjust them on the basis of the data.

Every ingredient brings their own challenges. Fats, milk derivatives and creams require temperature management through storing and dosing, while dehumidified air must be used for hygroscopic materials such as sugar and salt require the use of dehumidified air. Viscous ingredients require specific transport and dosage methods.

A turn-key partner like CEPI will be able to identify all such needs and provide the solutions required. Crucially, all these issues will be managed organically, coordinating complex processes in the most efficient way and producing data that is already integrated.

What solutions does cepi provide for the confectionery market? How do the turnkey solutions of real-time data work with this?

Our method is applied across the board. The confectionery manufacturers that work with us gain a modular and flexible system, access to an unparalleled technological offer and a tailor-made data management system.

Other than storing and dosing, we provide solutions such as independent invert sugar production, sugar milling with relative dosing system for the production of crystal sugar, management of liquid products with appropriate storage and conveying on the basis of their individual characteristics, storage and dosing of fats, pastes and cream. We provide rework technology for biscuit scrap, including sandwich biscuits.

In confectionery, accurate blending and dosing, all the way to the addition of inclusions, are fundamental. That is where our automation system and the data we provide will make a key difference, as the automation is so customized and the data so detailed. The dosing stations we provide span from modular hoppers, to broad spectrum dosing stations for minor ingredients, to the 3in1 station, a system which weighs and blends in a single unit.

Tech4Food

October 2021

CEPI: If your process needs it, we can do it

CEPI: If your process needs it, we can do it

“If your process needs it, we can do it. And if we can’t do it yet, we will develop it, just for you”. The company motto accurately portrays its mission. Where customization is not a plus but a must. Since 1985.

A new, technologically-advan- ced and environmental-friendly headquarter which tripled the production area. A global network of offices and technicians able to provide assistance to all customer needs. And cutting-edge solutions equipped with the most advanced technologies. CEPI, specialized manufacturer of bulk-handling systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes, approa- ches its 40th anniversary enjoying very good health. A family-run, Italian company with an international outlook, operating globally with a network of local partners spanning the five continents, and with offices in Malaysia to co- ordinate operations in the Asian market.

“Since 1985, we have been working with the most important companies from all sectors of food manufacturing”, Stefania Montalti, communications manager, explains. “We are currently moving into our new headquarters: after the exceptional 87% growth in the past decade, we have built a new facility that tripled our productive area to a total of 15,000 m2, with a 13,000 m2 factory space and the rest dedicated to offices. As we approach the 40th anniversary since our foundation, we designed our new home to be beautiful, but most of all, green and safe.”

CEPI’s new headquarters will be powered and heated by renewable energy, including a 430 kw/h solar system, radiant floor heating, total heat recovery, recovery of rainwater for irrigation, refills for electric cars, high efficiency heat pumps, increased insulation and high brightness shed. “They are also designed to completely safeguard worker safety – Montalti adds -, with microfiltration against fine dust in the air, welding gas distribution system, lighter-weight roof and swinging hooks.” The plant includes a 240 m2 testing and prototyping room fitted with metrology room, “which is a testament to our dedication to research and will help us provide even further customization to our customers, as well as food te-chnology assistance in developing recipes and mixes.”

Always in the forefront of innovation

CEPI’s vision has centered research, customization and flexibility since the very beginning. The company’s mission goes indeed beyond just assembling food machinery. “We build turn-key installations that manage the production line from storage to dosing, all the while developing specialized solutions to match diverse and ever-changing needs across the planet,” Stefania Montalti underlines. “CEPI brings to the table a global knowledge of materials, environments, and markets as well as the continued research that goes into developing around 300 unique systems every year.”

Born from the encounter of two visions: an engineer’s and a manufacturer’s, CEPI has grown into an ‘idea factory’ that puts technology squarely at the center of its work, developing around the very idea of turn-key: fully cu- stomized, fully in-house designed and manufactured thanks to the highly diversified handling technology it provides.

The right technology for all materials

CEPI’s offer includes multiple indoor and outdoor storing options in stainless steel or antistatic fabric, minisilos and dumping stations for medium production volumes and a broad spectrum of stations for the accurate management of micro ingredients. “Powders, granular products, liquids, fats. Macro, micro, medium volumes. Fermentation, cooling, fluidization, milling, blending, rework. Our motto is: if your process needs it, we can do it. If we can’t do it yet, we will develop it, just for you. Our technologies evolve to match each individual demand from the manufacturer side, leading to an unparalleled technological range”, Stefania Montalti highlights.

Materials are moved by clean and efficient conveyance systems designed to minimize the energetic impact. Dosing is handled in modular hoppers for powders and tanks for liquids, as well as the 3in1 station for the production of premix. Other applications include flour cooling, fermentation, sugar mills, invert sugar technology, salt solution sy- stems, fat and liquid tanks, fat cold metering, bread and biscuit rework systems including liquid rework of sandwich biscuits, and CIP or PIG washing system for a complete hygienization of tanks and pipes.

Turn-key, for real

CEPI provides a turn-key system that includes fully integrated automation, with production management through touch panels and software for process control, full traceability and warehouse of the management. Hardware and software design is done completely in-house. Each system is designed through a comprehensive study of the manufacturer’s processes that includes all operations from wa- rehouse to marketing, and customized to match analysis of raw materials, site evaluation, environment and consumptions.

“Turn-key means that the user of the system is completely independent as soon as we finish com- missioning and start-up, both in managing the system and in managing the data”, Stefania Montalti explains. “In CEPI, we like to say that our product is the bulk-handling system as a whole and not any specific technology, and our service is the customization. Last but not least, our installations come with integrated automation and are completely traceable, therefore all the data regarding the operations of the bulk-handling system is included in our project. We feel that a system that does not provide all the information about its operations cannot be called turn-key. Not only do we produce the data but we also offer total information exchange with any third party in the line.” And since every installation is different, CEPI’s tailor-made work would not be possible without a continuous dialogue with customers, and without a worldwide network of local partners who are able to provide technological and sales related support at all stages of the project.

Remote control: a company priority

One of latest industry trends that CEPI was able to comply with is the increasing preference for remote control of all operations, from any location and on all devices such as smart phones and tablet. CEPI is indeed able to provide all this alongside remote commissioning, maintenance and monitoring. The automation team provides full 24/7 remote support on all tools with live visualization on VPN network, management of production and intervention on the source code. Testing, optimization, start-up and training can be delivered remotely. Virtual and personalized tutorials and live assistance with dedicated devices are also included in the services provided.

“Globality, flexibility, expertise and dialogue: this is the special recipe behind a rich history of developments that includes too many technologies to list comprehensively”, Stefania Montalti highlights. “To name only a few of the most recent ones: the 3in1 station with vertical blender for the production of premix, the sandwich biscuit rework system adding to our existing rework solutions for bread and dry biscuits, the improvements making our microdosing station even faster and more flexible, and the zero environmental impact heat treatment for the total sanification and disinfestation of outdoor silos.”

International Bakery

September 2021

Product Spotlight: 3 in 1

Product Spotlight: 3 in 1

3 in 1: weighing, filtering and blending in a single unit. 3 in 1 station weighs the ingredient, separates air from product during pneumatic transport and comes with vertical blender for the production of premix to ensure the highest flexibility across a wide range of food sectors. 3 in 1 is fast, accurate and clean, delivering a homogeneous mix of powders even for quantities lower than 1% of the total weight, in the span of 3-5 minutes.

The 3 in 1 can be used to mix ingredients before dosing or in place of the dosing hopper. Its speed makes it very suitable for continuous mixing systems. In installations with multiple lines it can be combined with hoppers to achieve the highest flexibility in production.

Available in sizes from 60 to 1000 liters, it can be loaded pneumatically or by gravity. It is equipped with slide valve and extraction is by with rotary valve or feed screw.

The 3 in 1 is made in stainless steel and is ATEX conform. It comes with hygienic design and is easy to clean, fully inspectable and washable.

Integrated automation and full traceability.

Suitable for bread, pastries, ice cream, pasta, gluten-free products, cereal mix, cereal bars, baby food, functional food, spices mix, instant coffee and more.

As direct manufacturers of turn-key bulk-handling systems for every food market, CEPI provides multiple solutions for the weighing and accurate dosing of all powders and liquids in the recipe. Powder hoppers are stainless steel and modular and dosing can be continuous or batch, positive, by loss of weight, by volume or by weight. Liquid dosing is done in tanks or IBS controlled by electronic metering scale, with temperature and modified atmosphere control.

Micro ingredients such as salt, improvers, aromas, spices, starch, inclusions, and other additives are handled by broad spectrum high precision metering station Trimix, and special solutions are provided for the preparation, storing and dosing of salt solution and invert sugar and the cold and hot dosing of fats.

The dosing system comes with fully integrated automation of all operations including production management on PLC with HMI, full traceability and warehouse management on native software, total information exchange with SQL database and weight control in real time.

Company profile

Cepi designs, manufactures and installs bulk-handling systems for the storage, conveying and dosing of raw materials, as well as fully integrated automation and technologies to complete all production processes. A family-run company with an international outlook, CEPI is based in Italy and operates globally, with offices in Malaysia to coordinate operations in the Asian market and a network of local partners spanning the five continents. Since 1985, we have worked with the most important companies from all sectors of food manufacturing.

CEPI’s vision centers flexibility, customization and the continued research that goes into developing around 300 unique systems every year. We believe in build lasting relationships for lasting projects, through an ongoing conversation which concerns all their aspects: from process and product analysis with hygiene and safety management and food technology support, to engineering and control, manufacture, commissioning and service. All these stages are managed internally and with continuity through all operations and all-encompassing support, we give each project the care it deserves.

International Confectionery

June 2021

Family run with an international outlook

Family run with an international outlook

International Confectionery’s Editor, Kiran Grewal, sits down with Ignor Riccardi, Sales Director at CEPI spa, to discuss the company’s development and exciting new sustainable expansion.

Could you tell us more about CEPI’s history, its mission statement and the heritage of the business that inevitably shapes the company today?

CEPI was born in 1985 from the meeting between an engineer and a manufacturer. Combining their experience in designing and building machinery for the European food industry, Ceccarelli Pierdomenico (whose name and surname’s initial syllables gave CEPI its name) and Giuseppe Milanesi set out to create a company that wasn’t just a business venture but an idea factory. CEPI’s mission statement has not changed since our beginnings and goes beyond assembling machinery: we build turn-key installations that manage the production line from storage to dosing, all the while developing specialised solutions to match diverse and ever-changing needs across the planet. Our vision has always been centred around research as well as flexibility and customisation. Giancarlo Riccardi and Marino Montalti, who joined the direction a few years later, shared this focus on technology and customer-oriented approach, and shaped the sales and production departments around it.

In 2021, we are one of the major bulk-handling providers for the food industry globally, with offices in Malaysia to coordinate operations in the Asian market and a network of local partners spanning the five continents. We have worked for some of the most important companies from all food sectors of food manufacturing, designing, manufacturing and commissioning turn-key systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes. After building more than 10.000 installations the world over, we still consider ourselves a family-run company with an international outlook, whose most important product is not any single technology but the installation, and whose most important service is customisation.

How did CEPI adapt its working model throughout the pandemic? Did you face uncertain situations – how did you overcome them?

Because CEPI’s working model has always been flexible and involving a great deal of digital tools, the shift has not been hard for us. A large percentage of our operations can now be smoothly run remotely. We have developed tools to connect with new people, such as virtual tours of our factory and offices. Our products and installations can be explored through simulations and 3D animations, and we have developed webinars to showcase our technologies and share our expertise on topics as varied as food technology, automation and financing.

In terms of commissioning, assistance, and training, we were ready in many ways: we have always provided such services remotely and we have further boosted our processes to ensure that our projects are fully taken care of. Many of our installations have been assembled remotely, and we can count on a worldwide network of local partners who are able to provide technological and sales related support at all stages of the project.

Because of these reasons, and because of the huge effort from everyone in our team, we are proud to say that our production and turnover have stayed stable around 28M since 2019, despite the overall downturn in markets and the logistic problems created by travelling restrictions.

Could you tell us about the plans for the new HQ – how will it be powered, and will there be more room for production?

After the exceptional 87% growth in the past decade, we are building a new facility that will triple our productive area in the coming spring of 2021 to a total of 15.000 m2, with a 13.000 m2 factory space and the rest dedicated to offices. Our new home will be powered and heated by renewable energy, including a 430 kw/h solar system, radiant floor heating, total heat recovery, recovery of rainwater for irrigation, refills for electric cars, system high efficiency heat pumps, increased insulation and high brightness shed.

The layout of the new factory has been built through a detailed study of productivity and goods flows and we expect production to be much more centralised and rational, thanks not only to the added space but the optimisation of all processes and waste reduction as well. Other important additions include automatic vertical warehouse, customs approved place, dedicated loading area, silo washing department, and much extended upper areas up to 16 mt in height for the manufacture of outdoor silos on top of our existing tower.

What latest technologies and innovations have you seen at the company?

Sustainability is a key factor not only in our decision-making, but in that of food manufacturers as well! Because of this, we are working to expand the range of our reworking solutions, which already includes the recovery of bread and similar products as well as biscuit scraps both dry and liquid, with the latest addition being our systems for the reworking of sandwich biscuits.

When it comes to dosing, the 3 in 1 station is one of our most important innovations. It weighs the ingredient, separates air from product during pneumatic transport and at last blends, all in single unit. The vertical blender inside is a system to produce premix that ensures the highest flexibility across a wide range of food sectors. Fast, accurate and clean, 3 in 1 optimises mixing and production times and can be used to mix ingredients before dosing or in place of the dosing hopper.

We are also providing a new heat treatment for outdoor silos that ensures sanification and total disinfestation against pests of flour and micro-organisms such as bacteria and fungi. This treatment has zero environmental impact and doesn’t require downtime after application as it doesn’t generate residuals.

What are the latest trends and market insight you are seeing in the confectionery market?

The biggest trend we are seeing is towards healthy products. This includes bio food with related concerns about cultivation and storage, and nutraceutical/functional foods which add active components to provide added benefits such as reducing the risk of diseases and increasing energy, mental clarity, fitness and anti-aging.

Alongside this there is also interest in products perceived as traditional or authentic. Products from the past are associated with a simpler taste and fragrance and employing natural ingredients and a less processed recipe. In terms of manufacturing, this demands technologies that can improve the management of the raw materials and avoid intrusive processing.

Other challenges are the conciliation between these needs and economic concerns, the new distribution channels that will emerge and the support of sustainability efforts.

What are the benefits to automatic dosing systems and why is digitalisation and improvement of technology an important step for the company to grow?

CEPI provides fully integrated automation of our bulk-handling systems. Production is managed through multiple operator panel solutions, and our native software provides process control, warehouse management and full traceability as well as total information exchange through SQL database and communication with ERP or MES. Weighing control in real time is provided for all our storing and dosing stations, along with the management of all other variables involved such as temperature and pH. Hardware and software design is done completely in-house, which allows us to provide technical and human continuity through the development of a project that can become very specific and complex.

Each of our automation systems is tailor- made to match analysis of raw materials, site evaluation, environment and consumptions. It’s designed through a comprehensive study of the manufacturer’s processes that concerns all operations from warehouse to marketing to allow the inclusion of future projected productions. This highly customised system will not only ensure a unique and high-quality product, but also enhance traceability and communication with other software and ERP, provide higher efficiency and production volumes, reduce consumptions and pollutions and improve working conditions. Our systems also make productions more hygienic, with total separation between production and warehouse and optimise space in both areas.

What future projects will CEPI be working on and what can we expect to see going forward? We are expecting the economy to rebound, and with restrictions lifting we are expecting to meet people again in venues such as fair trades, but not only. All in all, we think there will be many opportunities for new projects which will put our new headquarters to good work! However, as we shift back into normality, we plan to integrate the solutions and tools we developed facing COVID-19 to make our working model even more flexible.

The new headquarters include a 240 m2 testing and prototyping room fitted with metrology room, which is a testament to our dedication to research and will help us provide even further customisation to our customers, as well as food technology assistance and assistance in developing recipe and mixes.

We are looking into insourcing as many processes as we can to offer an even more complete product to our customers, and we want to explore new markets such as meat and brewery. The new headquarters, as big an accomplishment as it is, is only just the beginning!

International Bakery

April 2021

Providing turn-key solutions for the bakery market

One of the main factors we consider when designing installations is the preservation of food properties and flavour. This outlook is built both into the development of our technologies and the way we design our automatic dosing systems. Our storing solutions are built in suitable top quality materials and are designed to be easy to clean, with multiple filtering and sifting systems to enhance food security. They can be fitted with technologies such as double-jacketing or dehumidification for hygroscopic products. We perform a study of room temperature and humidity and provide our customers with instructions for the correct maintenance of their working environments.

We have also developed an exclusive welding technique to prevent pollution and contamination in stainless steel equipment and our fabric silos employ antistatic HT Trevira fabric with patented technology to ensure equipotentiality. We provide a hot treatment to sanitise our outdoor silos, which removes microorganisms and infestations. The accuracy of our automatic dosing systems ensures precision in the dough, protecting the unique flavour of each recipe, and includes FIFO management of ingredients which greatly enhances the traceability process.

Protecting the quality of flour

For bakery lines and flour specifically we also provide fluidisation and technologies to ensure natural maturation and stability of temperature.

Correct and linear management of the dough temperature is essential in bread-making. Seasonal changes cause considerable variations to the temperatures of work areas and raw materials, impacting leavening times and creating unevenness in the finished product. CEPI offers a centralised cooling system for a gradual and automatic reaching of set temperature, based on the direct exchange of pre-cooled air through a fluidised bed and able to independently take the flour to the temperature required for further processing. This system eliminates the need for cooling agents such as cooled water or ice, which not only add unnecessary costs to your process but lead to instant decreases and unstable temperatures through time. The progressive cooling of the CEPI system guarantees higher stability and precision, and homogeneity in the dough with thermal exchange acting directly on every flour particle.

All storing solutions can be equipped with a fluidisation system that allows for chronological extraction with FIFO logic, greatly enhancing the traceability process. The flour oxygenation operated by the fluidised bed leads to a crucial improvement in the quality of the flour, with a faster but natural maturation that improves the flour’s rheological properties without using additives. Fluidised flour is much better for breadmaking, with better responses to all treatments from dough preparation to fermentation. The dough is more elastic and easier to work. It absorbs water more easily and keeps gas in more easily during leavening.

Bread made from well oxygenated flour is softer thanks to a more alveolar product, and more digestible as oxygenation allows for longer leavening. Accuracy throughout Accuracy is the necessary goal of any good bulk-handling installation for the food industry, as it serves the double purpose of protecting the unique flavour of the product and ensuring that all safety and health concerns regarding ingredients are met.

The systems we provide for bakery lines provide high accuracy both in dosing of macro ingredients such as flour and that of minor ones such as aromas and inclusions. Our automatic dosing systems cover every operation from loading to dosing, ensuring the repeatability and precision of the recipe, and as mentioned, we provide FIFO management for all products (even unpackaged ones) and full traceability for macro, medium and minor ingredients both powdered and liquid.

As well as the automation, we provide Trimix, a broad spectrum dosing solution for micro ingredients, as well as a blending and premixing station that can be used both to mix ingredients before dosing or in place of the dosing hopper.

Trimix is capable of handling a wide range of challenging materials such as powder milk, powder cocoa and salt. It has an easy-to-clean design with an air blade system to clean the bearings, and comes with technologies to prevent leakage in the surrounding environment and leftovers within the storing units or scale. It is suitable for continuous dosing in big production lines, without clogging or the formation of bridges even for hygroscopic ingredients such as crystal sugar.

The three in one station weighs the ingredient, separates air from product during pneumatic transport and at last blends, all in a single unit. The vertical blender inside is a system for the production of premix that ensures the highest flexibility across a wide range of food sectors, optimising mixing and production times as the blend is already homogenous before reaching the mixer. It is fast, accurate and clean, delivering a homogeneous mix of powders even for quantities lower than 1% in the span of 3-5 minutes. It can mix ingredients before dosing or be used in place of the dosing hopper, and its speed makes it very suitable for continuous mixing systems.

Fully automated

CEPI provides a turn-key system that includes full automation. The design of the dosing system is a delicate process that requires a close analysis of all the manufacturer’s processes in order to fully optimise their production. Not only is all of our hardware and software design done in-house, but we have refined this process to perfection. The systems we design are customised to match analysis of raw materials, site evaluation, environment and consumptions in order to guarantee taste and integrity of the final product. They cover all operations from loading to conveying to dosing, as well as operations such as washing or climatising.

On top of repeatability and constancy in the recipe, our automated systems provide full traceability of materials, enhance communication with other software and ERP, reduce consumptions, powders and pollutions, generally improve hygiene with total separation between production and warehouse, improve working conditions and reduce human error, optimise space in the production area and warehouse. Last but not least, our systems are easy to adapt or expand including the addition of new ingredients due to the flexibility of the process.

CEPI’s touch panels can be fully customised and are developed across both Siemens and Allen Bradley platforms. They handle recipe creation and management, ingredient and hopper parameterisation, synoptic overview with real time status and maintenance of utilities with manual command, loading of silos and other stations, and any other functions like washing and climatisation. Other options include CEPI’s native PLC and weighing processor with LCD display, for standard operations and one-line production processes.

CEPI’s native software Tracking System provides complete traceability including digitalisation of all ingredient movements, lot control with barcode system and warehouse management, greatly enhancing food safety and the optimal management of related alarms. Receiving and visualising data from the touch panels managing the production, Tracking System creates a history of storing and recipe production operations, providing production analysis with statistics of ingredient consumption, batch report with deviation analysis, stock visualisation and dynamic graphics illustrating product, recipe or lot trends.

CEPI’s automation system is interconnected and can exchange information with any third party in the line. Our solutions provide full horizontal and vertical integration, managing dialogue and data among our devices and those of other partners, after the dosing and before the raw ingredients management. All our data can be easily integrated with global ERP to achieve organisation-wide traceability. It can generate important information for not only for the production departments and management, but for departments such as quality control (lot usage information for each raw material) and purchases (schedule of raw material purchase, spare part purchase).

The sourdough revolution

Sourdough bread is tastier, more fragrant and healthier. Easy to digest and with a high nutritional value, it achieves a long-shelf life without preservatives, meeting the increasing demand for food manufactured through processes that preserve and enhance the natural properties of its ingredients.

Rye, wheat and multigrain breads but also pizza, focacce, brioches and crackers: in the last two decades, the defining factor in bakery manufacturing has been the rediscovery of sourdough, and the development of technologies that make artisan quality possible on an industrial level.

CEPI’s fermentation technology includes fermenters and bread re-work dissolvers for sourdough, as well as pre-dough and poolish. Our systems deliver precision and full control of all processes, as well as standardisation and repeatability of procedures. They can stand-alone or be easily integrated in the production process, allowing for bread making through both direct method and indirect two steps method, according to the needs of the manufacturer.

Modular and suitable for small, medium and big production volumes, our systems allow food manufacturers to produce healthy, natural and aromatic products while saving space, manpower, additives and yeast. The technology fully preserves the characteristics of the raw materials and meets the highest standards of hygienic production.

Automation with PLC control, with a flexible management that allows for both automatic and manual options for all operations.

One trend we are observing during the pandemy is self-production: people have rediscovered the art of making their own bread, pizza and focacce. For manufacturers, it would be interesting to provide mixes of ingredients for customers who want to prepare their own product. Our three in one station is the ideal match for this kind of production.

Overall the trend towards healthy products continues, including bio food with related concerns about cultivation and storage, and nutraceutical/functional foods which add active components to provide added benefits as well as nutritional. There is also high interest towards products perceived as traditional or authentic – products with a simpler taste and fragrance that employ natural ingredients and a less processed recipe. As well as this, a growing number of customers are interested in verifying the sustainability of food they eat, including consumptions of materials and energy.

DolciSalati&Consumi

March 2021

Tecnologie ‘buone come il pane’

Tecnologie ‘buone come il pane’

PLe competenze e l’esperienza di Cepi al servizio della panificazione. Grazie a una vasta gamma di attrezzature e soluzioni tailor-made per lo stoccaggio, il trasporto e il dosaggio delle materie prime. Partner strategico dell’industria alimentare dal 1985, anno della sua fondazione, Cepi progetta, costruisce e installa impianti chiavi in mano per lo stoccaggio, il trasporto e il dosaggio delle materie prime. Azienda a conduzione familiare con uno sguardo internazionale, Cepi ha sede a Forlì ma opera a livello globale grazie a una rete di partner nei cinque continenti e uffici in Malesia, per coordinare le opera- zioni nel mercato asiatico.

Partner strategico dell’industria alimentare dal 1985, anno della sua fondazione, Cepi proget- ta, costruisce e installa impianti chiavi in mano per lo stoccaggio, il trasporto e il dosaggio delle materie prime. Azienda a conduzione familiare con uno sguardo internazionale, Cepi ha sede a Forlì ma opera a livello globale grazie a una rete di partner nei cinque continenti e uffici in Malesia, per coordinare le opera- zioni nel mercato asiatico.

“La nostra missione va oltre l’assemblaggio di macchinari: costruiamo instal- lazioni chiavi in mano che gestiscono la linea di produzione dallo stoccaggio al dosaggio, sviluppando soluzioni specializzate per soddisfare esigenze molto diverse e in continua evoluzione”, spiega l’azienda che, forte di una conoscenza globale di materiali, ambienti e mercati, è costantemente impegnata nell’attività di ricerca che la porta a sviluppare circa 300 sistemi unici ogni anno.

“Forniamo automazione integrata di tutte le operazioni produttive, con gestione della produzione attraverso soluzioni touch panel e software nativo per il controllo dei processi, piena tracciabilità, gestione del magazzino e scambio di informazioni con altri software ed Erp”, aggiunge Cepi. “Ogni sistema è personalizzato sulla base di un’analisi approfondita delle materie prime, del sito e dei consumi, e uno studio completo dei processi del produttore”. I sistemi firmati Cepi coprono ogni operazione, dal caricamento al dosaggio, garantendo la ripetibilità e la precisione della ricetta così come la piena tracciabilità per macro, medi e piccoli ingredienti, sia in polvere che liquidi.

LA PANIFICAZIONE SECONDO CEPI

Cepi ha sviluppato impianti per tutti i tipi di pane: a pasta molle o dura, integrale o di granoturco, di segale, di mais o di soda, incluse focacce e piadine. Con l’obiettivo di fornire le soluzioni (e l’esperienza tecnoalimentare) necessarie per gestire al meglio ogni ingrediente, inclusi quelli comunemente impiegati nelle produzioni biologiche come quinoa, teff, amaranto, latte in polvere e fibre.

Stoccaggio e dosaggio

L’attrezzatura per lo stoccaggio comprende silos per interni ed esterni in acciaio inox o tessuto Trevira anti- statico. Mentre la stazione per il dosaggio di micro ingredienti è in grado di gestire un’ampia gamma di materiali ‘impegnativi’ supportando ricette molto diverse: con un dosaggio accurato di sale, miglioratori, aromi, spezie, amido, inclusioni e altri additivi comunemente usati nella cottura bio e senza glutine, come gomma xantana, lecitina, psillio e cellulosa. “È adatta al dosaggio continuo su grandi linee di produzione, facile da pulire e dotata di tecnologie per prevenire perdite e residui”, sottolinea l’azienda. “La nostra stazione 3 in 1 con miscelatore verticale è la scelta ideale per la produzione di premix: oltre a pesare gli ingredienti, filtra e miscela in un’unica unità, ottimizzando i tempi e creando una miscela già omogenea prima di rag- giungere il mixer. La stazione 3 in 1 è veloce, precisa e igienica. Ed eroga una miscela omogenea di polveri anche per quantità inferiori all’1% del totale nell’arco di 3-5 minuti. Può essere utilizzata anche al posto del- la tramoggia di dosaggio, e la sua velocità la rende molto adatta ai sistemi di miscelazione in continuo”.

Fluidificazione e raffreddamento

La farina trae grande beneficio dall’impiego di tecnologie come la fluidificazione e il raffreddamento, che garantiscono una maturazione naturale e temperature stabili. L’ossigenazione della farina operata dal letto fluido ne migliora sensibilmente la qualità, con una maturazione veloce ma naturale, senza bisogno di additivi. “La farina fluidificata è più panificabile”, spiega ancora Cepi, “con migliori risposte a tutti i trattamenti: dalla fermentazione alla preparazione dell’impasto, che è più elastico e più facile da lavo- rare, poiché assorbe acqua più facilmente e trattiene meglio i gas durante la lievitazione. Il pane fatto con farina ben ossigenata risulta quindi più soffice, grazie a un prodotto ben alveolato, e la maggiore durata del- la lievitazione lo rende più digeribile”.

Una gestione corretta e lineare della temperatura dell’impasto è essenziale, ma troppo spesso è soggetta ai cambiamenti stagionali e alle variazioni di temperatura negli ambienti di lavoro. Incidendo sui tempi di lievitazione e creando disomogeneità nei prodotti finiti. “Cepi offre un sistema di raffreddamento centralizzato che rende possibile il raggiungimento graduale della temperatura impostata, basato sullo scambio diretto di aria precedentemente raffreddata attraverso letto fluido e in grado di portare autonomamente la farina alla temperatura richiesta per ulteriori lavorazioni, eliminando il ricorso ad agenti refrigeranti”, sottolinea l’azienda. “Forniamo un raffreddamento progressivo che garantisce stabilità, precisione e omogeneità nell’impasto grazie allo scambio termico diretto su ogni particella di farina”.

Fermentazione

Pane di segale, grano e multicereali, ma anche pizza, focaccia, brioche e cracker. Negli ultimi 20 anni, il trend dominante nel comparto della panificazione è stata la riscoperta del lievito madre e lo sviluppo di tecnologie che rendono possibile la qualità artigiana- le a livello industriale. “I nostri sistemi consentono la panificazione sia con metodo diretto che con metodo indiretto a due fasi, garantendo precisione e pieno controllo di tutti i processi, nonché standardizzazione e ripetibilità delle procedure”, spiega l’azienda. “Modulari e adatti a piccoli, medi e grandi volumi di produzione, preservano le caratteristiche delle materie prime e soddisfano i più alti standard di produzione igienica”.

International Confectionery

March 2021

Automation and process control: traceability, hygiene and trends

CEPI provides a fully integrated automation of their bulk-handling systems, with production management through multiple operator panel solutions such as customised 4-15’’ operator panel on Siemers or Allen Bradley platform for nontypical processes, CEPI native PLC Leonardo for typical processes and weighing processor WP140 with LCD display for simple one line productions. Their native software Tracking System provides process control, warehouse management and full traceability with production statistics and data management, as well as total information exchange through SQL database and communication with ERP or MES.

Weighing control in real time is provided for all their storing and dosing stations, along with the management of all other variables involved such as temperature and pH.

Each of the automation systems is fully customised to match analysis of raw materials, site evaluation, environment and consumptions, and designed through a comprehensive study of the manufacturer’s processes. This regards all operations from warehouse to marketing in order to allow the inclusion of future projected productions. Hardware and software design is done completely in-house, which allows them to provide technical and human continuity through the development of a project that can become very specific and complex.

Traceability is key

The complete traceability of all ingredients is fundamental to achieve hygienic productions. CEPI’s native software Tracking System provides complete traceability of all powdered and liquid ingredients. This covers the digitalisation of all movements, lot control with barcode system and warehouse management, which greatly enhances food safety and the optimal management of related alarms. Receiving and visualising data from the operator panels managing the production, Tracking System creates a history of storing and recipe production operations, providing production analysis with statistics of ingredient consumption, batch report with deviation analysis, stock visualisation and dynamic graphics illustrating product, recipe or lot trends.

As well as this, automated systems allow remote control of all operations, ensuring that loading and production operations are completely hygienic and shielding against contamination. Both digitalisation and automation also protect operators’ safety by making distancing easier.

CEPI’s systems are tailored to the needs of each process, with flexible management that allows a manual option for all operations, while still supplying all necessary weighing and dosing information such as weights, times and temperatures. However the general preference is for automated operations. Even during automatic productions, operators in possession of the required authorisation level can always intervene to stop or adjust the process, for example by changing a recipe on the fly. All utilities can be commanded manually during maintenance.