Our equipment is compliant with ATEX directive 2014/34/UE and Regulation (EU) 2023/1230 and other applicable international directives and regulations.

Our equipment is compliant with national and international standards and regulations for

articles intended for contact with food.

Our equipment is designed to be easy to clean and allows total emptying.

Stainless steel is employed in machinery and piping.

Our equipment is welded in accordance with the law by licensed and trained operators.

In our fabric silos, we employ antistatic HT Trevira fabric with patented technology to ensure equipotentiality.

Tank washing systems such as CIP or PIG are available.

Our welded carbon steel and austenitic structural components are manufactured in a channeled system certified to international standard UNI EN 1090 up to execution class EXC3.

We provide multiple systems conform to standards EN ISO 80079-36:2016, EN ISO 80079- 37:2016 and EN 15089:2009, ensuring insulation against explosion and fire, including.

Safety systems include overpressure valve on silos, CEPATIC system on loading, dispersing valves, magnets, pressure switches, sensors and slide valves to stop the propagation of explosions and flames in the conveying system.

We also design and supply multiple high efficiency dynamic and static filters and other air treatement solutions with filtration class suitable for the food and pharmaceutical industries.

- Rotary valve with star rotor (EN ISO 80079-36:2016, EN ISO 80079-37:2016 and EN 15089:2009 standards

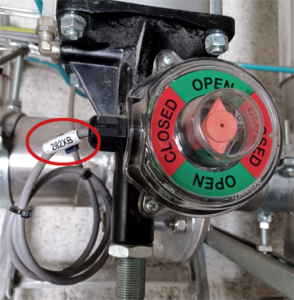

- Pneumatic slide valve explosions isolation system (certified according to EN ISO 80079- 36:2016 and EN 15089:2009 standards)

- Pneumatic flow diverter LIFT series (certified according to EN ISO 80079-36:2016, EN ISO 80079-37:2016

- Explosion insulation system (EN ISO 80079-36:2016 and EN 15089:2009 standards)

- Steel structural elements (305/2011 EN standard 1090-1:2012 and EN 1090-2:2018)