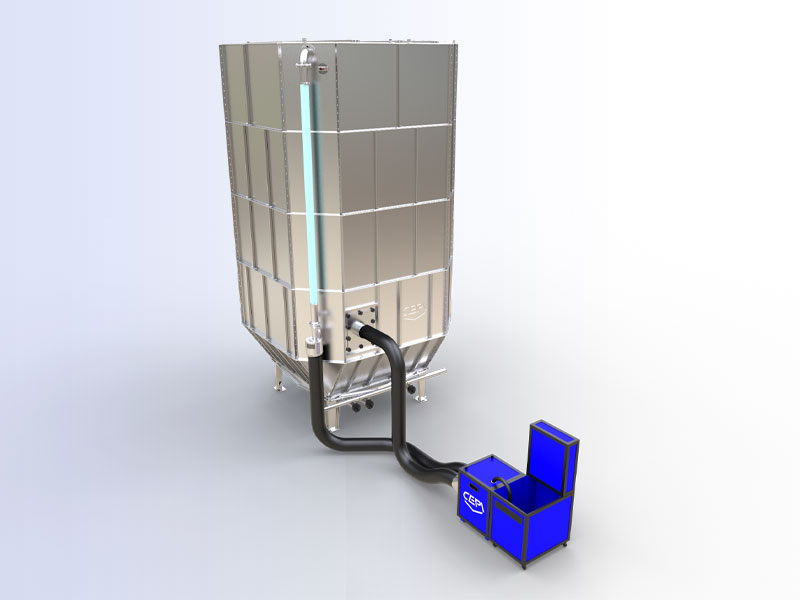

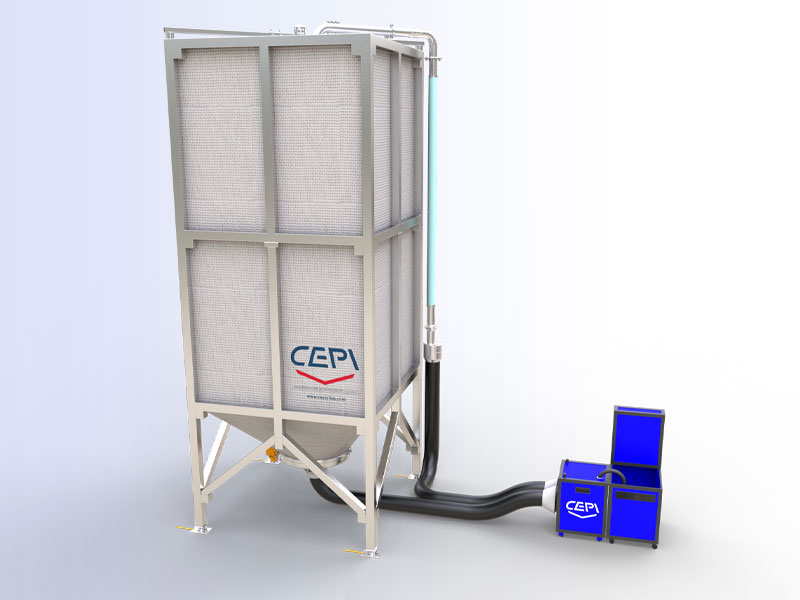

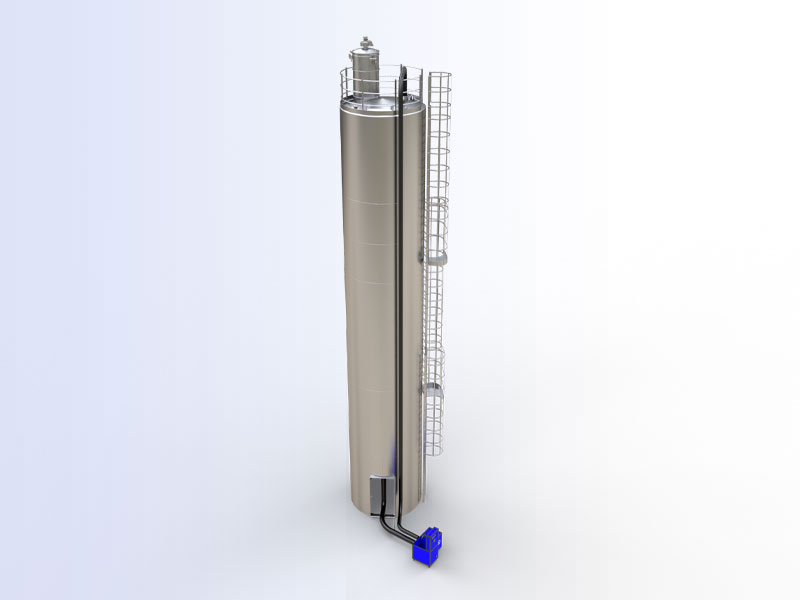

Heat treatment eliminates insect pests and microorganisms such as bacteria and fungi from all indoor and outdoor silos. The treatment is run by blowing high temperature air inside the silo through an ATEX certified air heater.

Heat treatment has total insecticidal efficacy against common flour pests such as tribolium, sitophilus and plodias, with a high mortality of all life stages included eggs. According to the tests we carried out, it has an excellent bactericidal and fungicidal power with a reduction of the charge up to by 100%.

The treatment with high temperatures is a technique with no environmental impact, and completely eco-sustainable as it doesn’t employ chemical products or toxic gases (such as phosphine or sulfuryl fluoride).

Heat treatment improves hygiene and food safety. It is ideal for bio productions as no chemicals are employed, and very used-friendly as it doesn’t require patents and doesn’t carry risks for the workers. It can be performed directly by food industry operators according to the needs of each production process.

Heat treatment doesn’t require downtime after application as there is no need to check for residuals from the treatment since no chemicals are employed.

It can be done repeatedly as needed (even weekly).

Features & Technologies