Company

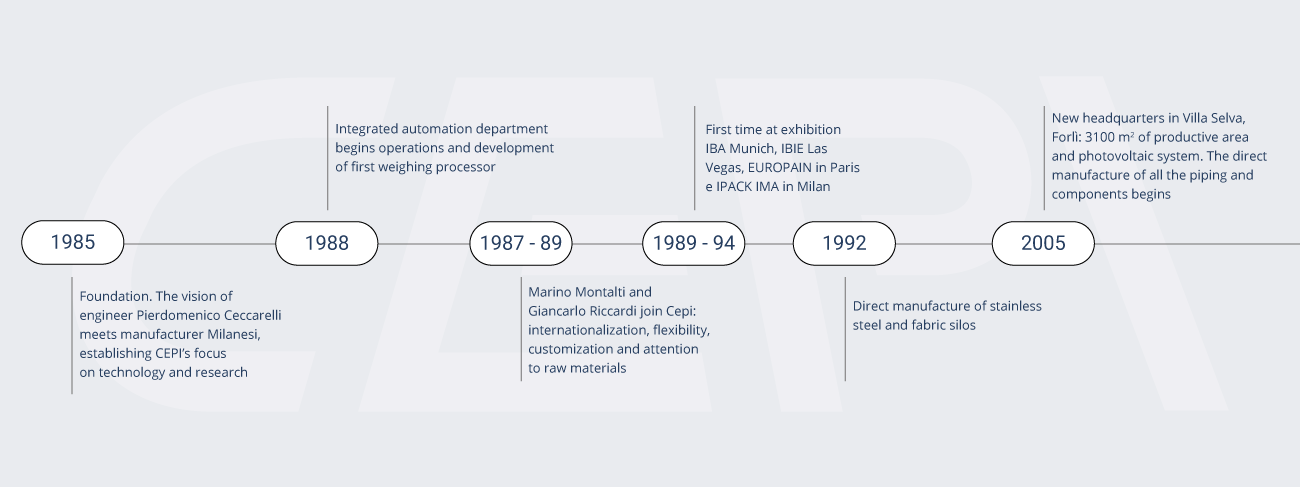

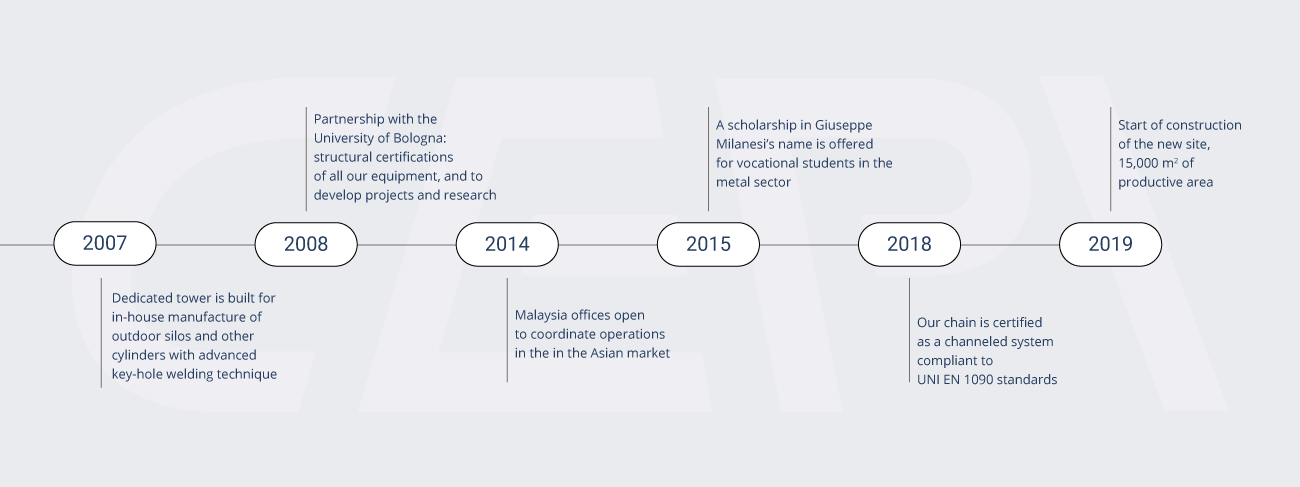

Cepi designs, manufactures and commissions bulk-handling systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes. A family-run company with an international outlook, CEPI is based in Italy and operates globally, with offices in Malaysia to coordinate operations in the Asian market and a network of local partners spanning the five continents. CEPI has centered research, flexibility and customization since inception. Our mission goes beyond assembling food processing equipment: we build turn-key installations that manage the entire production line from storage to dosing, and develop specialized solutions to match diverse and evolving needs of materials and processes across the planet, while preserving food properties and flavor and minimizing energy and material consumptions. Since 1985, we have worked with the most important companies from all sectors of food manufacturing.

Company

CEPI designs, manufactures and commissions bulk-handling systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes. A family-run company with an international outlook, CEPI is based in Italy and operates globally, with offices in Malaysia to coordinate operations in the Asian market and a network of local partners spanning the five continents. Since 1985, we have worked with the most important companies from all sectors of food manufacturing. Having centered research, flexibility and customization since inception, CEPI’s mission goes beyond assembling food processing equipment: we build turn-key installations that manage the entire production line from storage to dosing, and develop specialized solutions to match diverse and evolving needs of materials and processes across the planet. Our technologies are designed to preserve food properties and flavor while minimizing energy and material consumptions.

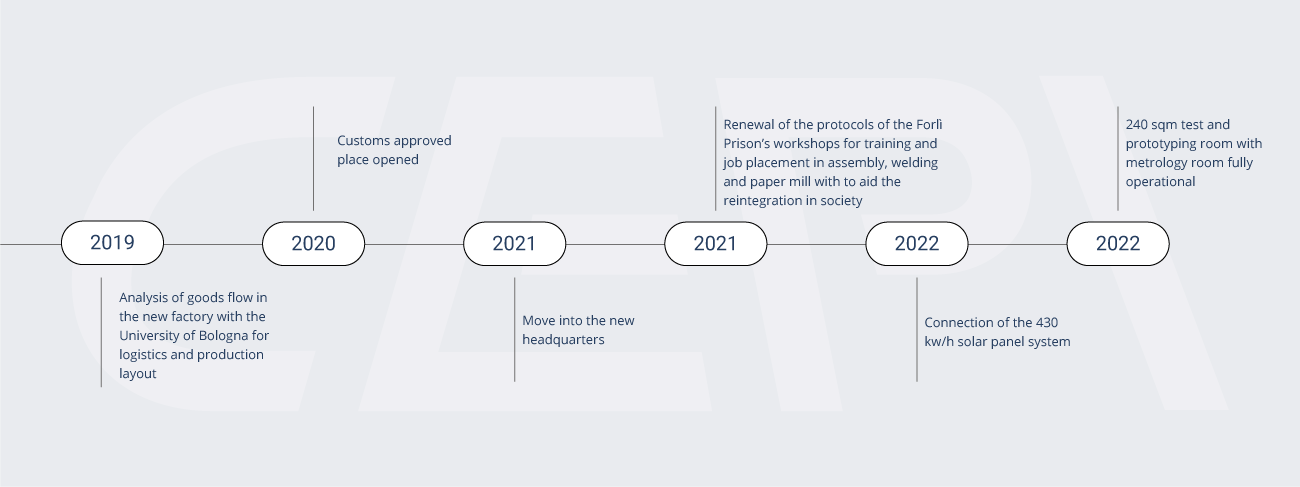

We consider the installation our product (rather than its individual parts) and customization our service. This vision extends to the breadth of services we provide, giving you access to a wealth of expertise and innovation at each stage of the project. We believe in build lasting relationships for lasting projects, through an ongoing conversation which concerns all its aspects: from process and product analysis with hygiene and safety management and food technology support, to engineering and control, manufacture, installation and service. All these stages are managed internally and with continuity through all operations and all-encompassing support, we can give each project the care it deserves. CEPI brings to the table a global knowledge of materials, environments, and markets as well as the continued research that goes into developing around 300 unique systems every year.

CEPI has made it a priority to nurture talent, fostering durable and trusting relationships with and among our people. We are proud of our qualified, reliable crew and their investment in seeing each project succeed and we believe it is our responsibility to support their personal and professional growth, with many training opportunities and a rich welfare program. CEPI has experienced continued growth through its history, and after the exceptional results of the past few years, after the exceptional results of the past few years, we have built a new facility in 2021 that tripled our productive area to a total of 15.000 m2. Our new home is powered and heated by renewable energy, designed to completely safeguard worker safety, and includes a 240 m2 testing and prototyping room with metrology room as a testament to our dedication to research.

Research

CEPI was born from the encounter between the vision of an engineer and a manufacturer. From these roots, it has grown into an idea factory that puts technology squarely at the center of our work. With the high levels of customization going into our projects and the diversity of needs we intercept across the globe, our research is always ongoing and has translated into unparalleled technological range.

Our motto: if a process needs it, we can do it. If we can’t do it yet, we will develop it. This is how we innovated pretty much all aspects of our field, matching general market trends and specific needs reported by our sales team, agents network, project managers, engineers, software designers and the commissioning teams themselves. Our R&D team itself aggregates engineering, manufacturing and food technology expertise. We monitor scientific and technological developments as well as feedback from markets and installations, and transform it into new tools. Not just for materials and processes, but with an important investment in hygiene and safety concerns, as well as sustainability and the preservation of food properties. Globality, flexibility, expertise and dialogue: this is the special recipe behind a rich history of developments that includes too many technologies to list comprehensively. You can find a selection in this article.

The new headquarters include a 240 square meters testing and prototyping room fitted with metrology room, which is a testament to our dedication to research and is aimed at creating a virtuous circle in our innovation. We will be able to perform more tests for our customers and provide them with more food technology assistance and assistance in the developments of their recipes.

CEPI has a developed a partnership with the University of Bologna for the structural certification of our and the development of projects and research on mechanical applications and materials testing.

Expertise

CEPI assists with every stage of the project: from product and process analysis with hygiene and safety management, to engineering and control, manufacture, logistics, installation, commissioning, service including helpdesk, monitoring, spares and assistance, and project managment overseeing all workflow. All our teams are highly qualified, combining rich expertise and decades-long experience with an orientation to innovating, as well as an ease in integrating other resources that ensures the highest levels of flexibility and continuity.

Our projects are developed with a deep knowledge of the materials, technologies and markets and a special commitment to hygiene and safety. CEPI provides integrated automation of all processes, with a team of 24 designers and programmers developing touch panels and traceability software in parallel to the mechanical plant. Our manufacture operations are part of a channelled system with personnel being regularly trained to ensure compliance. Food technology expertise guarantees a perfect match of our system with your raw materials, and is at your disposal during the development of recipe, assisting with your own research and innovation. Our Quality Control department will monitor all processes to confirm compliance with regulations and the hygiene and safety of all equipment.

Expertise

CEPI assists with every stage of the project: from product and process analysis with hygiene and safety management, to engineering and control, manufacture, logistics, installation, commissioning, service including helpdesk, monitoring, spares and assistance, and project managment overseeing all workflow. All our teams are highly qualified, combining rich expertise and decades-long experience with an orientation to innovating, as well as an ease in integrating other resources that ensures the highest levels of flexibility and continuity.

Our projects are developed with a deep knowledge of the materials, technologies and markets and a special commitment to hygiene and safety. CEPI provides integrated automation of all processes, with a team of 24 designers and programmers developing touch panels and traceability software in parallel to the mechanical plant. Our manufacture operations are part of a channelled system with personnel being regularly trained to ensure compliance. Food technology expertise guarantees a perfect match of our system with your raw materials, and is at your disposal during the development of recipe, assisting with your own research and innovation. Our Quality Control department will monitor all processes to confirm compliance with regulations and the hygiene and safety of all equipment.

Responsibility

CEPI’s Ethics Code is built around the 5 Ps of sustainable development in which the objectives of the 2030 Agenda adopted by the 193 UN member countries are grouped. The 5 Ps reflect the values that have always been implicitly shared in CEPI: giving back to our community, safeguarding people and their equality, protecting the planet and its resources, developing relationships of trust and transparency, building a future of fair and widespread well-being. Read the Ethics Code here.

To us, welfare means caring, listening and giving back. CEPI offers a wide array of benefits to our employees and their families to support their welfare at home and in the workplace. Benefits include healthcare, social care, education, entertainment, transports and canteen services, and are provided with the assistance of a no profit platform to ensure transparency, full fruition and support via welfare managers. We run a parallel program for our female employees to support conciliation between work, family and personal life, with an acknowledgement of the many barriers to parity they face in and outside of the workplace. Learn more.

Doing good by people and by the planet: CEPI aims to produce sustainable technology that protects the environment and gives back to the community it works with. Our main material is stainless steel and our systems and products have a long life, as well as a design that favors their revamping. Our installations including the pneumatic conveyance system are designed to optimise energy consumption. All our technologies from storing to dosing equipment to applications such as flour cooling systems are designed to minimize the consumptions of raw materials as well as waste. Our new headquarters were designed to be green and safe. Learn more.

CEPI has developed a partnership with the University of Bologna for research and projects on mechanical applications and materials testing. Working with various no profit organizations operating in our territory, we sponsor training and work placement programs targeted at vulnerable groups, and have developed a close relationship with local schools to carry out projects such as apprenticeship and internship opportunities. A scholarship in the name of Giuseppe Milanesi (one of our earliest partners) is offered to vocational students in the metal sector since 2015. CEPI reserves an annual budget for donations aimed at relieving the needy and has launched various projects for the recovery of our production scraps in collaboration with non-profit organizations in our area. Learn more.

All our processes have been certified to Occupational Health and Safety standard UNI ISO 45001, the international standard for occupational health and safety. Learn more.

We have received a legality rating certifying our ethical behaviour, conformity to legal standards and attention to proper management by the Italian Competition and Market Authority.

Hygiene and safety

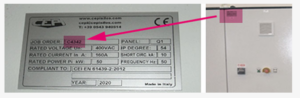

All our equipment and installations are designed to ensure full hygiene and safety in storing, conveying and metering operations. They are are compliant with all relevant international standards including ATEX directive 2014/34/UE, Regulation (EU) 2023/1230 and all international legislation for manufactured articles intended for contact with food.

Our welded carbon steel and austenitic structural components are manufactured in a channeled system certified to international standard UNI EN 1090 up to execution class EXC3.

A sizable portion of our research is directed to the innovation of our hygiene and safety measures. Depending on what is best for your installation, we can equip you with components and systems to prevent and contain explosions, flames and contamination, filters and other air treatement solutions, insulation, dehumidification and other technologies for specific weather condititions. We developed special materials and manufacturing techniques to protect the raw materials in our installations, such as antistatic fabric Trevira for indoor silos, and exclusive key-hole welding techniques to prevent residuals and pollution.

All our equipment is designed to be easy to clean and allows total emptying. Stainless steel is employed in all machinery and piping.