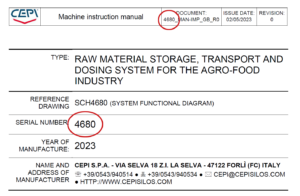

Process and product analysis with hygiene and safety management

Detailed review of production process with consideration to all needs and critical issues regarding raw materials, logistics, environment, climate and timing. Special attention is given to all hygiene and safety concerns with the supervision of our Quality Control department, and assistance from our food technology specialists is provided through the selection of materials and development of recipes.

Engineering and control

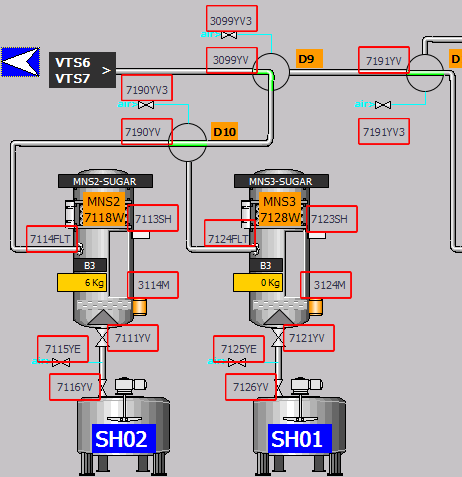

Mechanical and software design of customized turn-key systems from highly qualified and trained teams, within a work environment prioritizing the continuous updating of know-how and flexibility. Automation (including production management, weighing in real time of all silos and dosing stations and full traceability) is fully integrated and developed in parallel to the mechanical project, ensuring synergy and continuity of operations.

Direct Manufacture

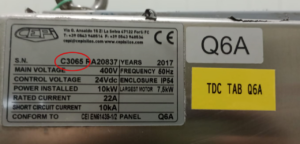

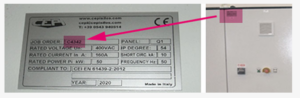

Direct manufacture of equipment and components compliant with all relevant international standards including ATEX legislation, in a channeled system certified to standard UNI EN 1090. Outdoor silos are built in dedicated tower with advanced key-hole welding technique to prevent contamination. All machinery and piping is in stainless steel with loading bags and other fabric parts designed and produced in in-house tailoring department, including patented antistatic Trevira fabric for indoor silos.

Project management

A team with resources from both technical and sales backgrounds oversees planning operations, integration of the workflow from all departments, interface with customer and other partners and problem solving at all stages.

Logistics, Installation, Commissioning

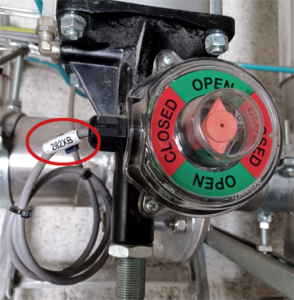

Planning and organization of delivery to all destinations and by all modes such as land, ship and air, with document support and interface with customs. Assembling on location and commissioning with testing and optimization of the integrated automation system.

Customer service

Technical support both remote and on site, assistance with repairs and maintenance, testing and training as well as certifications, shipments, assembling and commissioning. Highly specialised training including pre-emptive mechanical and electrical maintenance, troubleshooting, HMI training, hygiene and cleaning of equipment, simulation of the installation, automation and traceability processes, personalised video tutorials and local training of operators during launch.