CEPI aims to produce sustainable technology that protects the environment and gives back to the people we work with. Social and environmental responsibility is built into our ethos since the start: through our history, we have always sought to create the best working conditions for our employees, to reduce the footprint of our operations and to have a positive impact on our community. It is part of our mission to minimize the energy and material consumptions of our installations, to enhance people, ideas and territories and to grow in a sustainable way innovating the technologies of our sector.

In this page we detail the following areas of intervention:

- our Ethics Code, which is built around the 17 goals of the 2030 Agenda for Sustainable Development

- circularity and environmental sustainability of our products

- environmental sustainability of our operations (including waste management and our new headquarters, which was designed to be green and safe)

- welfare and safety of our employees

- community and territory

- hygiene and safety of our installation

The 2030 Agenda for Sustainable Development, adopted by all United Nations Member States in 2015, provides a shared blueprint for peace and prosperity for people and the planet, now and into the future. At its heart are the 17 Sustainable Development Goals (SDGs), which are an urgent call for action by all countries, all declaring themselves willing and able to achieve these goals together by 2030.

The 17 goals can be grouped in 5Ps, which have a deep meaning for us in CEPI and which therefore became the reference framework in our Ethics Code:

People Heart of technology: we didn’t choose this tagline at random. Not only are people the driving force of CEPI, they are above all its heart. Giving back is the founding value of our work, and translates into a concrete effort to leave a positive trace in the communities and territories we work with, protecting the dignity, equality and economic well-being of all the people involved and guaranteeing them care, listening and support

Planet We have been called custodians of raw materials, and it is a title we take quite seriously. We are committed to creating systems that preserve the properties of food with the same care with which we choose the materials useful for our production and with which we protect the resources of our territory, which nourishes all of us and which we intend to nourish in turn. Environmental sustainability has always been a fundamental factor in our choices, and we are committed to implementing all the processes necessary to ensure that our technologies and services protect the planet’s natural resources and future generations

Partnership Lasting relationships for lasting projects. It is not only our machines that have a long life, but also the relationships we establish with employees, customers, suppliers, and all the social partners affected by our work. Our goal is to create strong bonds such as those made daily in our workshop, imbued with mutual trust and transparency, and based on a shared sense of responsibility and the desire to build together

Prosperity To us, prosperity means possibility. To build is our job and it is this knowledge that allows us to imagine a fair and safe future for everyone. It is our deep conviction that this planet is rich in resources and opportunities that must be accessible to all, and that it is our duty to contribute to the equality of human beings regardless of gender, race, color, religion, disability, nationality, sexual orientation, or any other characteristic that gives rise to discriminatory attitudes

Peace A family-run company, yes, but with an international outlook. The emigration roots that are part of CEPI’s history have always naturally prompted us to look beyond national borders, and to create relationships based in collaboration, understanding and mutual growth with the countless partners we have cultivated on the five continents. CEPI wants to continue to promote integration, inclusivity and diversity in the deep conviction that peaceful relationships and mutual respect are key elements not only for the development of our company, but for the future we are all trying to build together

We have carried out an assessment with Warrant Garden and Studio Fieschi in regards to Environmental, Social, and Governance areas and further a materiality assessment according to GRI (Global Reporting Initiative) standards, in order to identify the most relevant topics for our stakeholders. We have also carried an assessment on the circularity of our installations, which you can read about in the next section.

The assessment of our performance found us especially strong in terms of the following goals:

The assessment found that:

4 QUALITY EDUCATION CEPI places great value on training, both internally through the provision of training activities for employees and through collaborations with local schools and educational institutions, leading to many apprentships and hiring opportunities for students.

5 GENDER EQUALITY There are women in top management positions and there is no discrimination whatsoever against the female gender. Furthermore, CEPI runs a parallel benefits program for their female employees in order to support them in conciliating between work and personal life.

7 AFFORDABLE AND CLEAN ENERGY CEPI produces energy from renewable sources. The headquarters are a high efficiency building equipped with a 430 kw/h solar system and is ready for connection to district heating.

8 DECENT WORK AND ECONOMIC GROWTH CEPI’s headquarters is a high energy class building, with the factory in class D and offices in class A. With regards to production processes, great attention is paid to sustainability, to maintaining a low impact on the environment and to the health of workers. For example, pickling is avoided in favor of brushing, which costs more but reduces pollution and makes the work environment healthier. The issues of decent work and the right to work are completely in line with the corporate vision of CEPI, which is also very active on a social level and has hired many people from various fragile groups into the company

9 INDUSTRY, INNOVATION AND INFRASTRUCTURE CEPI is already engaged in activities and initiatives that pertain to 9.2 target (inclusive and sustainable industrialization), particularly in regards to inclusion towards employees. CEPI shows that they are committed to protecting diversity in the workplace. They also give great importance to flexible working practices, to support employees in managing their home-work balance. Sustainable and inclusive industrialization is also pursued by choosing reliable suppliers as close as possible to the CEPI headquarters. The construction of the new headquaters fully meets the 9.4 target (upgrade infrastructure and retrofit industries to make them sustainable).

12 RESPONSIBLE CONSUMPTION AND PRODUCTION CEPI’s main material is stainless steel which is highly recyclable. CEPI has always designed their systems to be easily repairable and modifiable over the years. Customer revamping activities are frequent. There is also attention to the reduction, reuse and recycling of packaging.

16 PEACE JUSTICE AND STRONG INSTITUTIONS CEPI is in the process of developing an official Social and Environmental Responsibility Policy, including a section dedicated to legality.

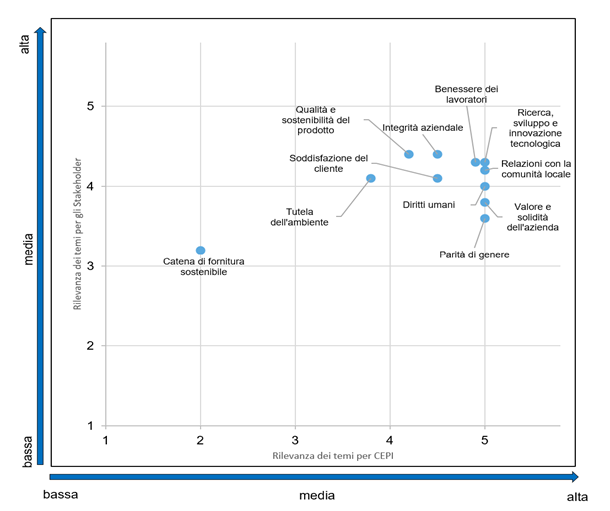

What is meant by materiality? According to the GRI, materiality represents the threshold where a sustainability topic becomes meaningful for the company and its stakeholders, and therefore must be managed responsibly and included in the sustainability reports. A materiality analysis is therefore carried out by:

- identifying priority issues for the company through the involvement of senior management

- identifying priority issues for stakeholders through the analysis of documentation relating to corporate stakeholders, their point of view on sustainability and their expectations in this area

The materiality matrix is thus represented by a graph that shows the position of the most relevant sustainability issues, from the point of view of the company (Y axis) and of the stakeholders (X axis).

The topics in consideration in our materiality assessment were:

- Company’s value and solidity

- Business Integrity

- Product quality and sustainability

- Research, development and technological innovation

- Environmental Protection

- Sustainable supply chain

- Welfare of workers

- Human rights

- Customer satisfaction

- Relations with the local community

- Gender equality

And this is how our materiality matrix looks like:

We are developing our Sustainability Strategy and our Social and Environmental Responsibility Policy on the basis of this matrix, and we are committing to keep vigilant and improve where necessary on all areas that are significant to us and our stakeholders. We further commit to:

- establish strategic objectives for innovation, production, operations, management, economic and financial planning introduce specific procedures and actions to facilitate the implementation of this policy

- continuously evaluate the performance of our strategy and improve it as needed

- produce an annual sustainability report that examines our performance

- keep ourselves updated on all legal requirements and acquire all necessary certifications to support our claims

- encourage our business partners to implement a sustainability policy

- encourage our staff to pay attention to how their actions in the course of their work affect the environment and society

We take a long-term view when we design a bulk-handling system, in order to create the most flexibile solution for each food manufacturer. The design is based on a close analysis of the user’s process, based on information that goes well beyond the purely technical. Our method involves all departments from werehouse, to production, technical, purchasing and marketing, to include projection of future productions. This is what makes our installations very easy to adapt to future developments.

One of our strengths is the ability to bring new life to installations that would otherwise be decommissioned. This activity, known as revamping, makes it possible to extend the useful life of the plants indefinitely: systems that we built 30 years ago are still functioning efficiently.

Our goal is to provide turn-key solutions. We see our systems as organic: storage, dosing, conveying and their automation must be regarded in their totality, and in the way they interact with each other. This is crucial to achieve effective customization, which in turn is what makes installations very durable.

Our working method therefore achieves twin goals: it makes users independent and meets their specific needs, as well as ensuring that their process is efficient and sustainable, providing them with a durable installation that fits with the circular economy model.

A circular product is a product that operates within the circular economy model: they have reduced or no need for virgin resources and are designed with the end of their life in mind.

The circular economy model is rapidly establishing itself both in international policies and in consumption models, as an essential element of the transition towards sustainable development. It aims to enhance the recycling and reuse of raw materials and products, in order to reduce the consumption of virgin resources. The implementation of a circular economic model is based on three principles:

- Use renewable resources the circular economy favors the use of renewable materials, placing attention to the sustainability of their origin and ensuring that they are not generated through a excessive exploitation of natural resources

- Preserve products and materials in use the circular economy favors activities that they retain value in the form of energy, labor and materials This leads to the need to design to increase life, reuse, remanufacture and recycle to maintain products, components and materials in circulation in the production system Circular systems have a use effective of bio-based materials, encouraging many different uses before the substances nutrients are returned to natural systems

- Reducte waste the circular economy favors the reduction of waste production through a design that pays attention to the end of life of products and packaging

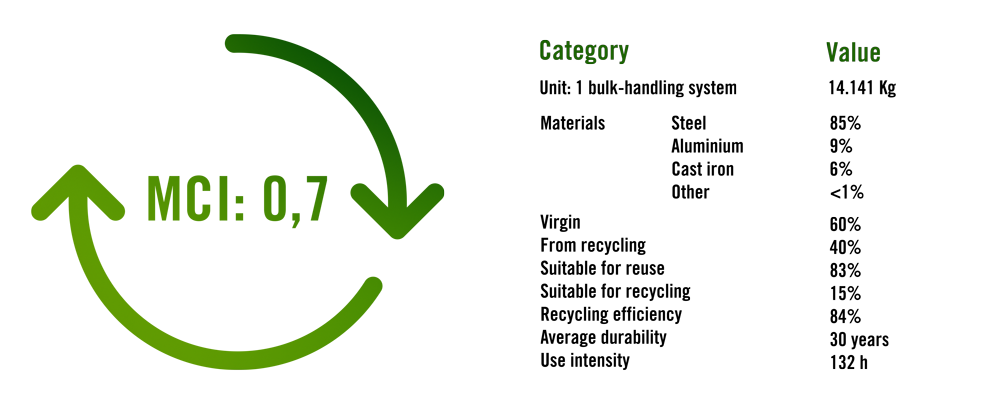

To gather more detailed information about the circularity of our product, we have commissioned a study from Warrant Garden and Studio Fieschi, who apply the method identified by the Ellen Mac Arthur Foundation, one of the most authoritative international organizations in the field of the circular economy. The Ellen Mac Arthur Foundation has developed the Material Circularity Indicator (MCI), that aims to measure the level of circularity of a product, evaluating information about the origin of materials, information about the characteristics of the product and its use, and information about the end of life of the product.

CEPI has been the first company in Italy to commission the evaluation of a system (as opposed to a single application). Our circularity indicator for the average system right now is 0,7 on a scale between 0 and 1, which is considered pretty high. Our installations are very durable, and the materials are rated this way:

- 83% suitable for reuse

- 15% suitable for recycling

- 2% disposal

- 84% recycling efficiency

All in all we are quite satisfied, especially as the final indicator was penalized by sector wide factors, in particular this past year’s materials crisis, which has made it much harder to procure recycled steel. We expect that once we return to our usual supply chain the indicator will automatically go higher, and we have made its increase one of our strategic goals.

The durability of our installations is 30 years on average, which we attribute to our design method. It makes it clear how strategic a turn-key approach that aims for flexibility is, and how much efficiency, durability and sustainability overlap.

It is said that the circular economy favors diversity and systematic thinking. These are also the foundations of our working model. We have always privileged modularity, versatility and adaptability, and we have an organic view of our installations, consideration how the various elements work together and influence each other.

Other than the circularity of our installations, other factors contribute to the sustainability of our products and operations:

- All our technologies and components are reliable and resistant over time, with a long life cycle. They comply with all the requirements of the sector standards, such as the ATEX Directive 2014/34/EU, the Regulation (EU) 2023/1230 and all international legislation for products intended to come into contact with food

- Stainless steel is our main material

- We develop all our applications with the minimization of consumptions and waste in mind (some examples: our 3in1 blending station is designed to optimize mixing and production times, whereas our sugar invert technology aims to facilitate and reduce process times. Our flour cooling system provides a gradual cooling that runs by batch on fluidized bed, which reduces energy consumptions dramatically compared to rapid cooling processes. The heat treatment we provide for silos is a method for sanitization and total disinfestation which has zero environmental impact, and is completely eco-sustainable as it doesn’t employ chemical products or toxic gases.)

- We supply custom-made solutions with a 40 years of experience in designing installations that maximize energy and materials efficiency

- We are direct manufacturers of almost all equipment in our installations and work exclusively in our factory in Italy, with mostly local suppliers

- Our automation is very scalable and customizable, specific down to the single utility, which results in a general optimization of all processes

We are committed to minimizing waste production and we practice the principles of reduction, re-use, and recycling in all our operations.

All our waste is traced on register and disposed in compliance to EU Directive 2018/851 with the method that has the least impact on the environment and is most appropriate for the material.

All our metallic waste including steel, iron and copper as well as wood, washing solutions, electric cables and printer toner is re-used.

Gas cans are safely disposed of according to the relevant legislation.

We take responsibility for the safe handling and storage of waste at all office and factory locations. We provide appropriate training for staff, suppliers and customers as well as promoting environmental awareness.

Our new home was designed to be a low impact building that is powered and heated by renewable energy, and includes:

- 430 kw/h solar system

- radiant floor heating

- total heat recovery

- recovery of rainwater for irrigation

- refills for electric cars

- all systems operating with high efficiency heat pumps

- increased insulation

- high brightness shed

- curtain walls with low exchange coefficient glazing

Our new headquarters completely safeguard worker safety, with microfiltration against fine dust in the air, welding gas distribution system, lighter-weight roof and swinging hooks.

We deeply believe in the value of giving back: from our beginnings we have been convinced that the people we work with should benefit from what we do. This has

translated into welfare policies aimed at listening to and caring for our employees and supporting their personal and professional growth. We believe it is our responsibility to protect their health and safety and to conduct our business legally and ethically.

CEPI was awarded as Welfare Champion by Welfare Index PMI, a selection promoted by Generali Italia of the most virtuous small and medium-sized Italian enterprises, chosen from more than 6,500 participants in the survey. Sandra Ceccarelli, our Legal Representative and CFO, represented us at the event. Discover all details here.

On top of contractual welfare, we provide a a wide array of benefits to our employees and their families with the assistance of a no profit platform to ensure transparency, full fruition and support via welfare managers. Read more about our welfare program.

CEPI does not discriminate in employment opportunities or practices on the basis of race, color, religion, disability, national origin, genetic information, sex (including pregnancy), age, sexual orientation, gender (including gender identity and expression), marital status, citizenship status or any other characteristic protected by applicable law. Our policy of non-discrimination in employment applies to recruitment, hiring, compensation, promotions, transfers, discipline, demotions, terminations, layoffs, access to benefits and training and all other aspects of employment.

All our processes in the offices and factories have been certified to Occupational Health and Safety standard UNI ISO 45001.

We have received a legality rating certifying our ethical behaviour, conformity to legal standards and attention to proper management by the Italian Competition and Market Authority. We choose our business partners based on legal compliance, always performing due diligence to ensure they fall within required standards.

CEPI Goal 5 of the 2030 Agenda aims to achieve gender equality and empower all women and girls: this means achieving equal opportunities between women and men in economic development, eliminating all forms of violence against women and girls and ensuring equal rights at all levels of participation. Historically attentive to equality issues, CEPI has always recognized the numerous barriers to equality that women face inside and outside the workplace, and their difficulty in balancing work and personal life. The BLU DONNA project, active since 2019, provides additional welfare services dedicated only to female workers and aimed at improving work-life balance. In 2023, we have chosen to draw up a Strategic Plan and formalize, systematize and communicate more intensely the actions we implement, in the profound belief that word, visibility and normalization are fundamental steps for achieving truly equal participation.

CEPI’s actions belong to 10 major areas: Career Management, Process Management, Pay Equity, Parenting and Care, Work-Life Balance, Prevention of Abuse and Harassment, Psychophysical Wellbeing, Training, Management and Communication System. The long introspection and great work we carried out to define the Strategic Plan have converged in a Decalogue, which aims to summarize our vision and our commitment in ten simple points, in the hope that it will be welcomed and shared by our partners.

The gender equality of our processes has been certified according to the PdR UNI 125 standard.

We have made a concrete effort to leave a positive trace in the communities and territories we work with, not only by directly supporting its most vulnerable groups but through the creation of many training and work placement opportunities with other local no profit organizations as well as collaborations with schools and university.

- we are partners of the protocols for the Forlì’s prison workshops, which train and provide work to detainees in assembly, welding, carpentry and paper milling to aid their reintegration in society. CEPI commissions welding work, pallets and panels on the machine, as well as artistic pieces from the Manolibera laboratory for decorative use in our headquarters, in Christmas baskets or as exclusive gifts to our customers and collaborators. The welding workshop, which CEPI strongly wanted and supported, was launched in 2020 and in addition to job creation through internships and regular hiring provides high-level argonist training, including teaching technical drawing and how to read it. The parties involved in the protocol have recently established themselves as a social enterprise in Altremani, of which Davide Saputo, our Head of Factory and Director for Health and Safety, is a partner

- we have created a scrap recovery project with CavaRei, a local non profit organization providing care and housing to people with vulnerable background, as well as work in their sustainable workshop. Our PVC scraps are transformed by the hands of their women guests into shoppers, badge holders, card holders and pen cases

- we are partners of the Romagna Oncological Institute (Istituto Oncologico Romagnolo), a no profit organization in our territory which has been engaged in the fight against cancer since 1979, with activities including research, therapy, awareness raising, improvement of quality of life and dignity

- we work with local no profit organizations such as Techne and Domus Coop to develop training and work placement programs targeted at vulnerable groups

- we have a close relationship with local schools such as the Salesiani Institute and its professional training center Cnosfap, the State Technical Technological Institute Marconi, the Pascal Comandini Higher Institute and offer many apprenticeship and internship opportunities

- a scholarship in the name of Giuseppe Milanesi (one of our earliest partners) is offered to vocational students in the metal sector since 2015 by the Ceccarelli and Milanesi families

- we have developed a partnership with the University of Bologna for research and projects on mechanical applications and materials testing, as well as the analysis of the goods flow the development of the production layout in our new headquarters

- we reserve a yearly budget to make monetary donations that aim to alleviate those in need as well as advance education efforts and promote

environmentally friendly practices

Our equipment is compliant with ATEX directive 2014/34/UE and Regulation (EU) 2023/1230 and other applicable international directives and regulations.

Our equipment is compliant with national and international standards and regulations for

articles intended for contact with food.

Our equipment is designed to be easy to clean and allows total emptying.

Stainless steel is employed in machinery and piping.

Our equipment is welded in accordance with the law by licensed and trained operators.

In our fabric silos, we employ antistatic HT Trevira fabric with patented technology to ensure equipotentiality.

Tank washing systems such as CIP or PIG are available.

Our welded carbon steel and austenitic structural components are manufactured in a channeled system certified to international standard UNI EN 1090 up to execution class EXC3.

We provide multiple systems conform to standards EN ISO 80079-36:2016, EN ISO 80079- 37:2016 and EN 15089:2009, ensuring insulation against explosion and fire, including.

Safety systems include overpressure valve on silos, CEPATIC system on loading, dispersing valves, magnets, pressure switches, sensors and slide valves to stop the propagation of explosions and flames in the conveying system.

We also design and supply multiple high efficiency dynamic and static filters and other air treatement solutions with filtration class suitable for the food and pharmaceutical industries.

- Rotary valve with star rotor (EN ISO 80079-36:2016, EN ISO 80079-37:2016 and EN 15089:2009 standards

- Pneumatic slide valve explosions isolation system (certified according to EN ISO 80079- 36:2016 and EN 15089:2009 standards)

- Pneumatic flow diverter LIFT series (certified according to EN ISO 80079-36:2016, EN ISO 80079-37:2016

- Explosion insulation system (EN ISO 80079-36:2016 and EN 15089:2009 standards)

- Steel structural elements (305/2011 EN standard 1090-1:2012 and EN 1090-2:2018)