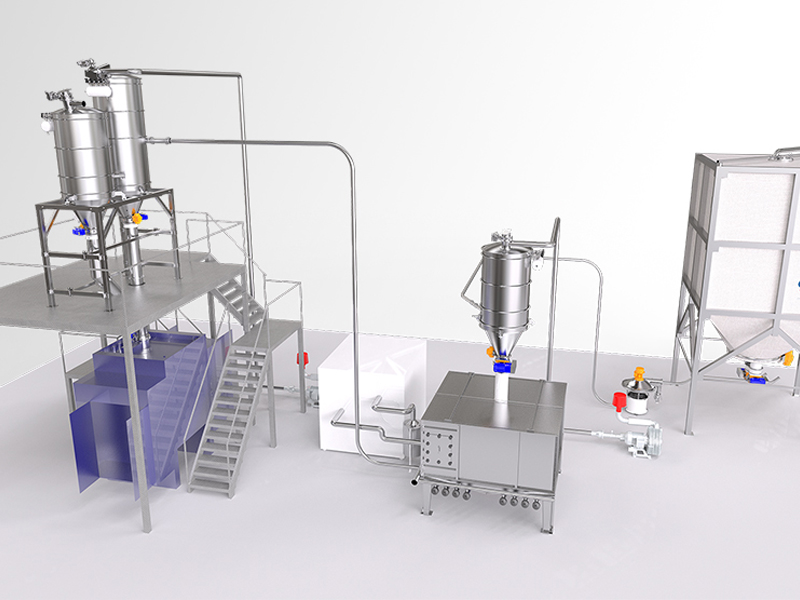

Correct and linear management of the dough temperature is essential in bread-making and similar processes. Seasonal changes cause considerable variations to the temperatures of work areas and raw materials, impacting leavening times and creating unevenness in the finished product. CEPI offers a centralized cooling system for a gradual and automatic reaching of set temperature, based on the direct exchange of pre-cooled air through a fluidized bed. With constant temperature of flour in the mix the final product is constant all year round.

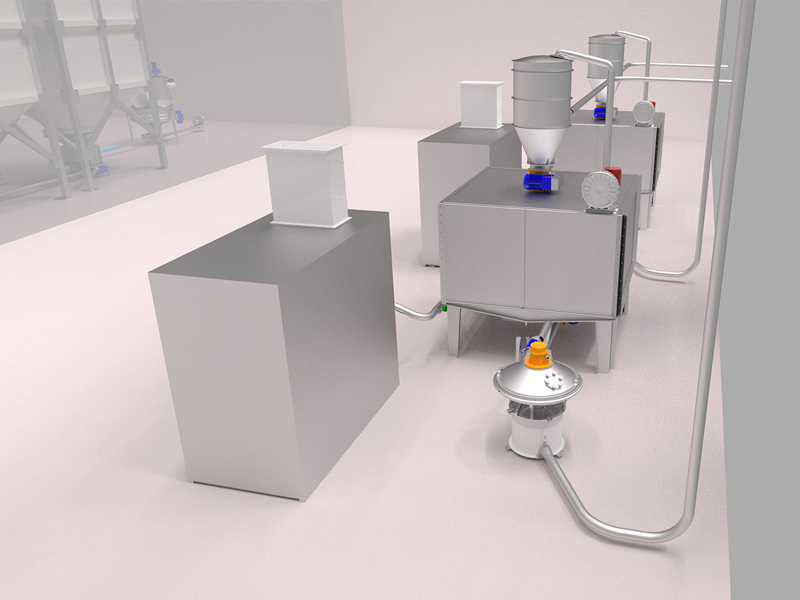

With an increased exchange capacity and a bigger air flux, our system has been recently perfected to automatically and independently take the flour to the temperature required for further processing. As such, it is a highly rational and accurate system that eliminates the need for cooling agents such as cooled water or ice, and the constant manual intervention they require.

Cooling agents not only add unnecessary costs to your process but lead to instant decreases and unstable temperatures through time. The progressive cooling of the CEPI system guarantees higher stability and precision, and homogeneity in the dough with thermal exchange acting directly on every flour particle. CEPI cooling system leads to standardization of production and finished product while diminished costs and reduction of human error.

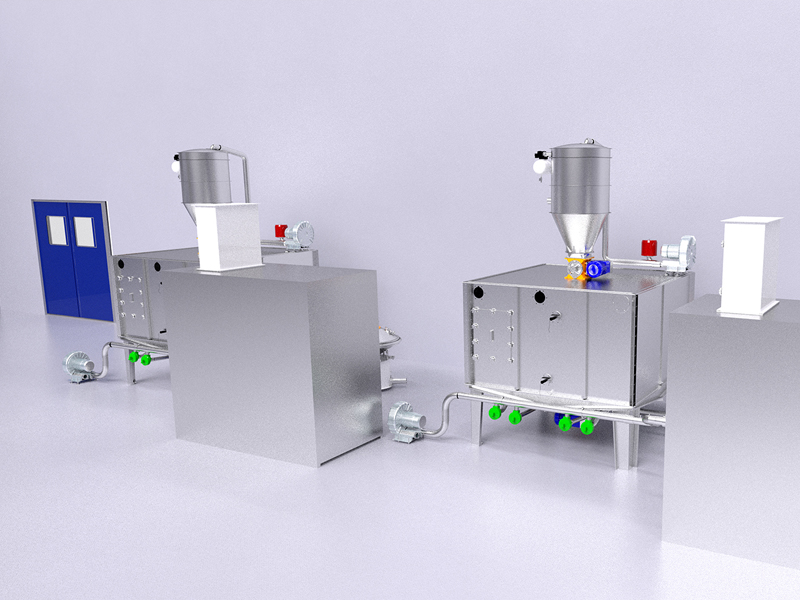

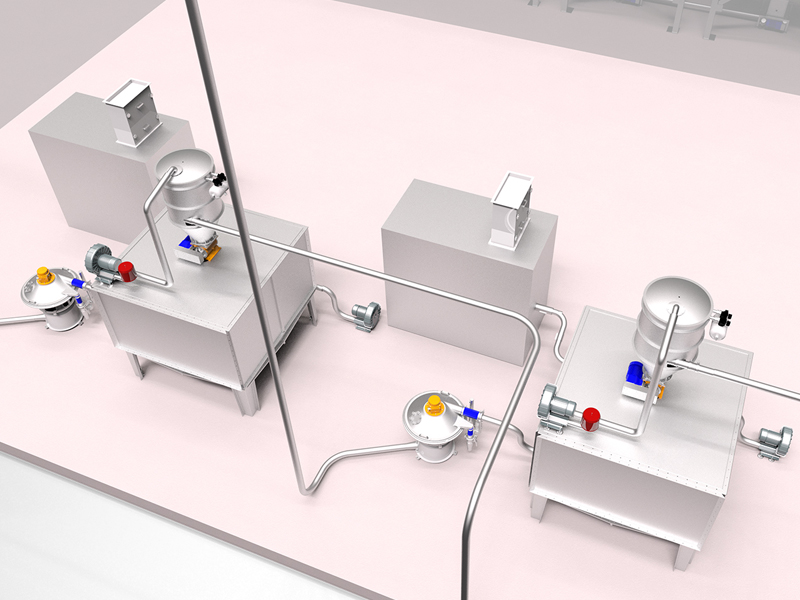

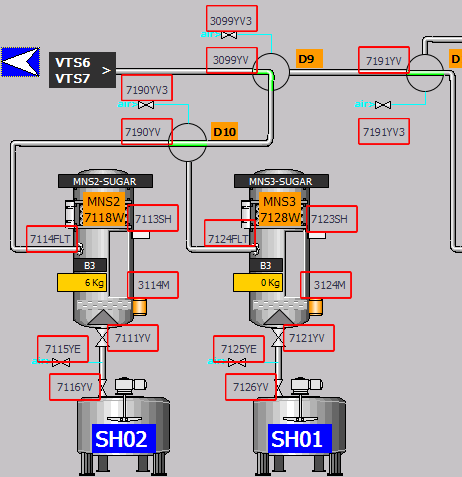

Like all our technologies, it is highly versatile with various options for dimension and thermal capacity. It is a modular system based on the specific cooling needs and consumption rates of each installation, and is designed to ensure full hygiene and safety and in compliance with all relevant international standards including ATEX legislation. There is no exchanger on the conveying lines and therefore no clogging in the pipes and no loss of time and resources to pure and restore the lines. CEPI cooling system is fully integrated with the storing, conveying and metering installation and provided with weighing in real time, integrated automation and full traceability.

Features & Technologies