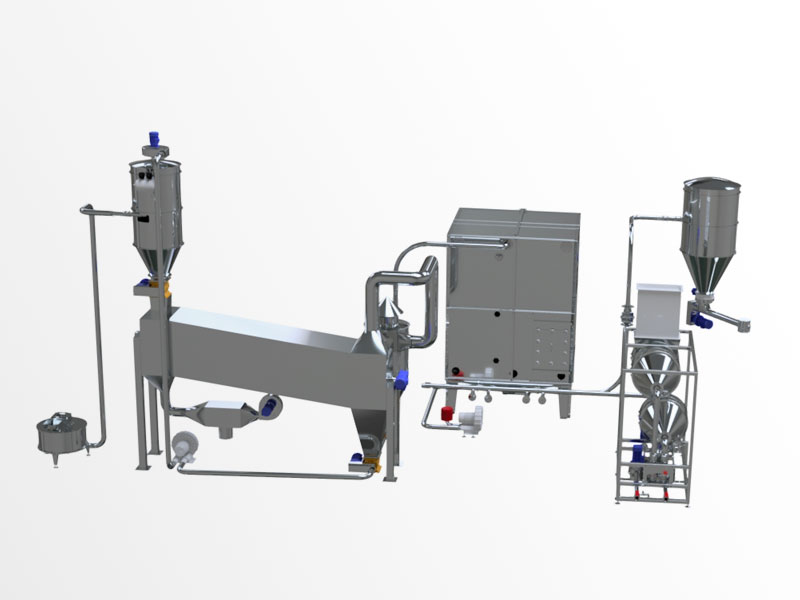

Fully automated rework systems for bread and similar products such as toasts, loaves and sandwiches. The final product can be fed back into production in place of flour, sold, used for animal feed, or worked again to produce croutons or bread crumbs.

Biscuit rework systems are also completely automated are re-use the powders on the production line. Product can be put directly on the conveying line.

Reworking production scraps is good for the planet and leads to excellent return on moderate investments within a short time period. The process eliminates the need to store scraps and guarantees a high quality end product with no loss of proteins compared with the flour used in the beginning of the process.

Features & Technologies