Other than the circularity of our installations, other factors contribute to the sustainability of our products and operations:

- All our technologies and components are reliable and resistant over time, with a long life cycle. They comply with all the requirements of the sector standards, such as the ATEX Directive 2014/34/EU, the Regulation (EU) 2023/1230 and all international legislation for products intended to come into contact with food

- Stainless steel is our main material

- We develop all our applications with the minimization of consumptions and waste in mind (some examples: our 3in1 blending station is designed to optimize mixing and production times, whereas our sugar invert technology aims to facilitate and reduce process times. Our flour cooling system provides a gradual cooling that runs by batch on fluidized bed, which reduces energy consumptions dramatically compared to rapid cooling processes. The heat treatment we provide for silos is a method for sanitization and total disinfestation which has zero environmental impact, and is completely eco-sustainable as it doesn’t employ chemical products or toxic gases.)

- We supply custom-made solutions with a 40 years of experience in designing installations that maximize energy and materials efficiency

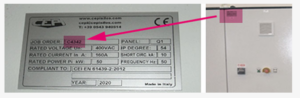

- We are direct manufacturers of almost all equipment in our installations and work exclusively in our factory in Italy, with mostly local suppliers

- Our automation is very scalable and customizable, specific down to the single utility, which results in a general optimization of all processes

We are committed to minimizing waste production and we practice the principles of reduction, re-use, and recycling in all our operations.

All our waste is traced on register and disposed in compliance to EU Directive 2018/851 with the method that has the least impact on the environment and is most appropriate for the material.

All our metallic waste including steel, iron and copper as well as wood, washing solutions, electric cables and printer toner is re-used.

Gas cans are safely disposed of according to the relevant legislation.

We take responsibility for the safe handling and storage of waste at all office and factory locations. We provide appropriate training for staff, suppliers and customers as well as promoting environmental awareness.

Our Waste Management System has been rated Excellent through an independent review by Sfridoo.