Flour

Hygienic macro and micro storing and automated metering for all types of flour, including: rye flour, common wheat flour, durum wheat flour, gluten free flour, whole-wheat flour, oat flour, spelt flour, maize flour, rice flour, barley flour, millet flour, teff flour, amaranth flour, quinoa flour, buckwheat flour, bean flour, pea flour, lupin flour and others.

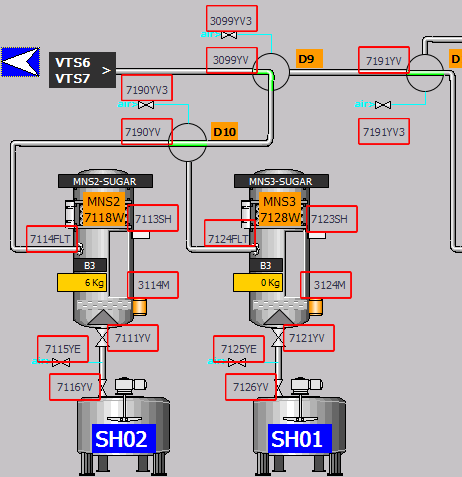

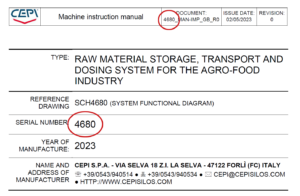

Sugar

Hygienic macro and micro storing in controlled humidity environment and automated metering for granulated sugar and cane sugar. Mill for crystal sugar to create an always fresh and controlled product in complete independence, tailored to the particle size and quantity requirements of each production. Micro ingredient dosing station for continuous metering or loss-in-weight metering. Tanks for liquid sugar with metering via centrifugal and volumetric pumps and CIP washing system.

Oil & fats

Hygienic storing and accurate metering of oil including olive oil, sunflower oil, maize oil, rapeseed oil and rice oil. Optimized solutions for any oil requiring special treatment. Tanks for modified and controlled atmosphere. Cooled tanks and pumping system with piping systems cooled through food grade glycol. Manual or automatic dosage with centrifugal and volumetric pumps.

Yeast & sourdough

Highly versatile solutions for bread, pastries, pizza, focaccia and more, allowing the utmost flexibility in the selection and employment of ferments according to any need arising from your process, final product, climate, and such. Our technology can be used to many ends: to produce poolish with brewer’s yeast, to replace brewer’s yeast with mother dough, or to add mother dough and inject flavor and fragrance in the bread. Our fermentation processes increases shelf-life and makes bread more easily digestible, while saving space, manpower, additives and yeast.

Salt & Additives

Fully automated station for the hygienic storing and accurate metering of micro ingredients such as mineral salt, chemical yeast, thickeners, preservatives, colouring agents, improvers, vitamins, spices and sweeteners. Optimized solutions for any additive requiring special treatment. Storing in outdoor solutions with humidity control in the silo. Storing of abrasive product in stainless steel silos and stations conform to ATEX directive.

Glucose & Syrup

Production, storing and metering of glucose syrup, corn syrup, high fructose corn syrup, maple syrup, golden syrup, cane syrup, agave syrup, honey syrup and others. Manual or automatic metering with centrifugal and volumetric pumps and conveyance with flow meters and mass-flow fillers. Complete management of all materials including sugar, glucose, corn, fructose, cane juice, sorghum juice, maple sap and agave nectar. Optimized solutions for any syrup or material requiring special treatment.

Cocoa

Hygienic macro and micro storing in controlled humidity environment of cocoa with any fat percentage. Management of cocoa with fat percentage higher than 12% in cooled pneumatic conveyance system. Microingredient dosing station for continuous metering or loss-in-weight metering. Optimized solutions for any cocoa requiring special treatment.

Eggs

Hygienic storing of eggs in climatized and insulated tanks with controlled temperature. Manual metering from bins or automatic metering with centrifugal and volumetric pumps and conveyance with flow meters and mass-flow fillers. Completely automatic CIP washing system for a complete hygienization of tanks and pipes. Optimized solutions for any egg product requiring special treatment.

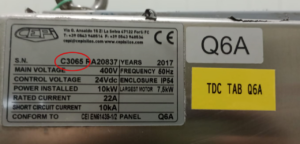

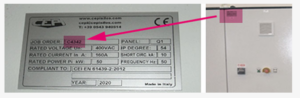

All machinery conform to ATEX legislation.

Weight control in real time of all silos and dosing stations. All operations are managed by fully integrated touch panels for production control, loading, washing, climatization and maintenance of utilities and software providing full traceability.