Long Pasta

Installations for all types of long pasta, including spaghetti, bucatini, linguine, vermicelli, ziti, cappellini, mafalde and any other. Hygienic macro and medium storing and automated metering of durum wheat semolina, corn flour, rice flour, pea flour, lentil flour, or materials such as teff, quinoa, amaranth and fibers which are frequently involved in gluten free and bio productions. Silos can be equipped with insulation, climatization and dehumidification systems, and loaded directly from truck, or from other silos, or from bag and big bag dumping stations. Single or multiple automated extraction and fluidization for accurate FIFO management. Centralized flour cooling system for a gradual reaching of set temperature. Sifting systems to ensure food security.

Short Pasta

Installations for all types of short pasta, including farfalle, fusilli, garganelli, maccheroni, penne, rigatoni, tortiglioni and any other. Hygienic macro and medium storing and automated metering of durum wheat semolina, corn flour, rice flour, pea flour, lentil flour, or materials such as teff, quinoa, amaranth and fibers which are frequently involved in gluten free and bio productions. Silos can be equipped with insulation, climatization and dehumidification systems, and loaded directly from truck, or from other silos, or from bag and big bag dumping stations. Single or multiple automated extraction and fluidization for accurate FIFO management. Centralized flour cooling system for a gradual reaching of set temperature. Sifting systems to ensure food security.

Fresh Pasta

Installations for all types of short pasta, including cappelletti, fettuccine, gnocchi, lasagne, pappardelle, passatelli, ravioli, strozzapreti, tagliatelle, tortelli and any other. Hygienic macro and medium storing and automated metering of common wheat flour. Silos can be equipped with insulation, climatization and dehumidification systems, and loaded directly from truck, or from other silos, or from bag and big bag dumping stations. Single or multiple automated extraction and fluidization for accurate FIFO management. Centralized flour cooling system for a gradual reaching of set temperature. Sifting systems to ensure food security.

Cous cous

Installations for cous cous, with hygienic macro and medium storing and automated metering of durum wheat semolina. Silos can be equipped with insulation, climatization and dehumidification systems, and loaded directly from truck, or from other silos, or from bag and big bag dumping stations. Single or multiple automated extraction and fluidization for accurate FIFO management. Centralized flour cooling system for a gradual reaching of set temperature. Sifting systems to ensure food security.

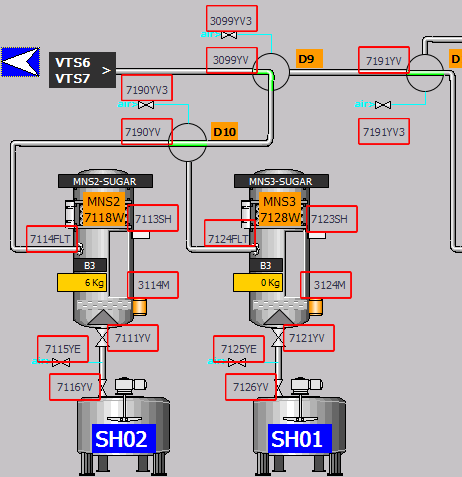

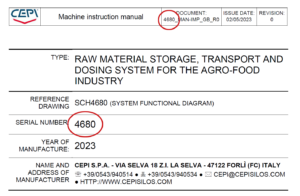

Fully automated station for the storing and high precision metering of micro ingredients such as salt, coloring agents and aromas. Liquid tanks and CIP washing system for a complete hygienization of tanks and pipes. Customized solutions for any ingredient requiring special treatment.

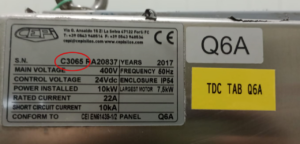

Weight control in real time of all silos and dosing stations. All operations are managed by fully integrated touch panels for production control, loading, washing, climatization and maintenance of utilities and software providing full traceability. All machinery compliant with ATEX legislation and suitable for abrasive products such as salt.

Bio & Gluten free

Bio and Gluten free installations for the all food productions, including confectionery, bakery, pasta, dairy, premix, baby, functional and sports food, and pet food.

Hygienic macro and micro storing and automated metering of materials such as quinoa, teff, amaranth, powdered milk and fibers which are frequently involved in gluten free and bio productions. Silos can be equipped with insulation, climatization and dehumidification systems, and loaded directly from truck, or from other silos, or from bag and big bag dumping stations. Single or multiple automated extraction and fluidization for accurate FIFO management. Centralized flour cooling system for a gradual reaching of set temperature. Sifting systems to ensure food security.