For this Slovenia installation for an icecream producer, we built a set of three doublejacket stainlesssteel silos for the storage of powderedmilk, sugar and whey. They are fitted with anticondensation and dehumidification systems, conveyance to multiple lines and all necessary safety systems such as systems against loading overpressure, anti-explosion hatch, bursting disk, recovery filter and air exhaust.

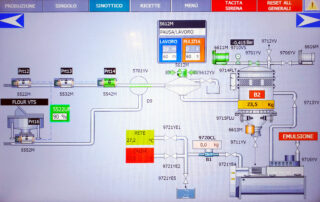

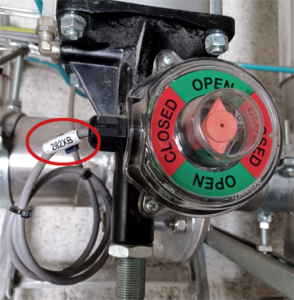

Bakery installation in Asia with multiple biscuits, cake and wafer lines. In the gallery, you can see the outdoor storing of flour as well as indoor storing of medium and micro volumes of cocoa, milkpowder and starch, multiline distribution and transport, sugar milling, multiple dosing points, cip washing system and automation with touchpanel.

Medium and micro ingredients management for a petfood installation: battery of Big Bag dumping stations, two micro ingredients storing and dosing units, Bag dumping station, electrical switchboards and fully integrated automation.

This installation for a biscuits manufacturer in central Italy includes storing solutions for medium and minor ingredients such as cocoa and salt, as well as the complex transport system we developed, with sifting and multiple dosing points in multiple lines.

Installation for confectionery manufacturer in France with outdoor storing of flour and cooling on loading to ensure temperature control. Extraction by vibrating cone and transport through in-house manufactured ATEX conform rotary valve.

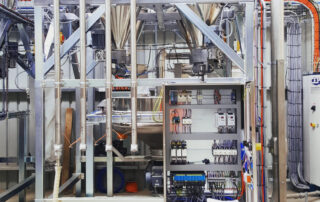

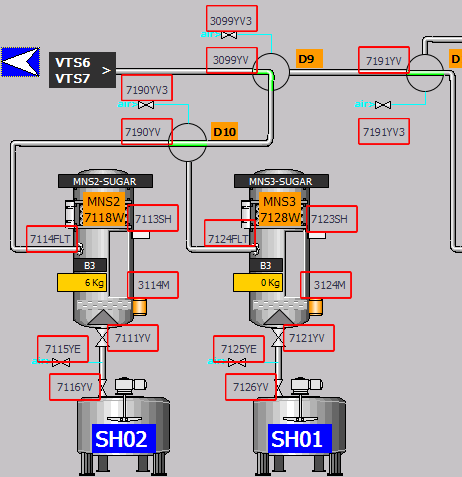

Bulk-handling installation for a sugar producer in Northern Italy: take a look at our sugar milling and fat cold dosing technologies, with feeding on mixer and integrated automation.

Biscuits installation in Serbia with storage and dosage of multiple liquids and powders in macro, medium and micro quantities, as well as clean in place system, full automation and traceability.

Check out an Invert Sugar system in Russia: preparation, storage and dosage of invert sugar, fully automated with PLC and HMI.