Sourdough is a mixture of water and flour fermented by a set of microorganisms including lactic and acid bacteria and yeast, which are naturally found in the flour. Sourdough bread is tastier, more fragrant and healthier. Easy to digest and with a high nutritional value, it achieves a long-shelf life without preservatives, meeting the increasing demand for food manufactured through processes that preserve and enhance the natural properties of its ingredients.

Rye, wheat and multigrain breads but also pizza, focacce, brioches and crackers: in the last two decades, the defining factor in bakery manufacture has been the rediscovery of sourdough, and the development of technologies that make artisan quality possible on an industrial level.

Why is sourdough so good?

Sourdough bread has a longer shelf life than brewer’s yeast bread. It delays starch retrogradation and the staling of bread. This is because sourdough is more acidic and less prone to develop degenerative bacteria and moulds.

Sourdough bread is easy to digest as leavening is longer: starches are metabolized and broken by the microorganisms in the dough, making it easier for the body to process them. With sourdough, there is no need to use additives and improvers to break the starch and to aid flour tightness during the process.

Sourdough increases the hydration of proteins and creates a more uniform sponginess.

Sourdough gives the finished product better organoleptic characteristics and a more complex aromatic profile. It develops aromatic aldehydes and adds a sour note, improving taste and fragrance.

Explore a bulk-handling installation for sourdough bread

History: from brewer’s yeast to sourdough

One of the biggest challenges right now for industrial food production is matching quality with volume and standardized processing. Historically, leavening the bread through the brewer’s yeast was the industry standard, as production was faster and high-performing. However, the final product saw a loss in fragrance and taste, as well as being harder to digest.

Sourdough was made with methods such as adding water and fruit sugars, and then adding this product to the dough as yeast. For the longest time this was the domain of artisan manufacturing, because it was a highly empirical method that relied on the style and method of each individual producer, without an exact knowledge of the bacteria in the sourdough. This was too unstable a process from an industrial perspective as the recipe was difficult to repeat and generally reliant on a single person controlling very changeable parameters.

The identification of the bacteria and micro-organisms in the sourdough made it possible to create an easily repeatable recipe. With the evolution of the technology controlling physical parameters such as times, temperatures and pH, finally sourdough production became possible on an industrial scale.

Large volumes of production can now be automated and managed by non-specialized operators for all the diverse fermentation processes – the black rye bread common in the Northern and Eastern parts of Europe relies on a more acid dough, while the white bread from the South based on soft wheat flour or semolina has a less acid note but a wider bouquet. As well as this, the longevity of products fermented with sourdough meets the need of modern food distribution – making it possible to achieve a large spatial and temporal distance between production and consumption points.

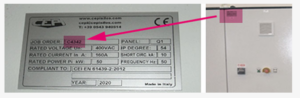

Tanks in stainless steel, easy to clean and equipped with CIP or PIG cleaning system

CEPI’s technology

To intercept consumer interest in high quality products, manufacturers need technologies that can combine natural processing and competitiveness. All sourdough fermented products have a high quality claim that can help manufacturers expand the market of any sort of bread, including loaves and slices.

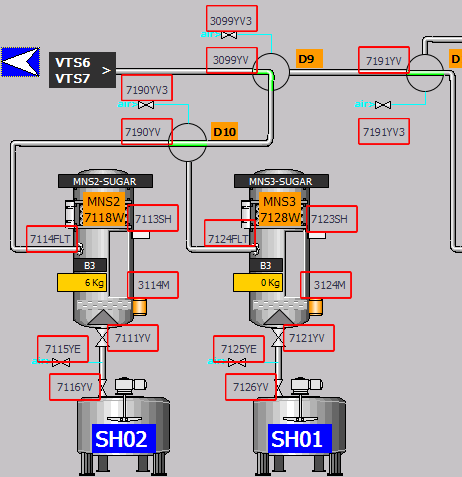

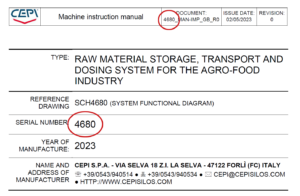

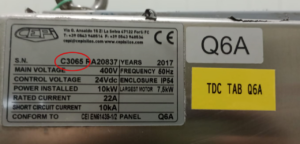

CEPI’s fermentation technology has been developed to achieve this goal: we provide fermenters and bread re-work dissolvers for sourdough, as well as pre-dough and poolish. With a deep knowledge of the materials involved and of all aspects of the process, we offer flexible solutions that deliver precision and full control of all processes, as well as standardization and repeatability of procedures.

Modular and suitable for small, medium and big production volumes, our systems allow food manufacturers to produce healthy, natural and aromatic products while saving space, manpower, additives and yeast. The technology fully preserves the characteristics of the raw materials and meets the highest standards of hygienic production.

CEPI’s systems can stand-alone or be easily integrated in the production process, allowing for bread making through both direct method and indirect two steps method, according to the needs of the manufacturer.

We provide fully integrated automation with PLC control, with a flexible management that allows for both automatic and manual options for all operations.

Head to our Fermentation page for more detailed information, to download the product sheet and to watch the video.

To discuss your project and get a quote, get in touch at cepi@cepisilos.com. We are eager to build the perfect solution for your product!