Cepi has opened the doors to our new home. After the exceptional growth in the past decade, we have built a new facility that tripled our productive area to a total of 15.000 m2, with a 13.000 m2 factory space and the rest dedicated to offices. The new headquarters include a 240 m2 testing and prototyping room fitted with metrology room, which is a testament to our dedication to research. We will be able to perform more tests and provide more food technology assistance to our customers.

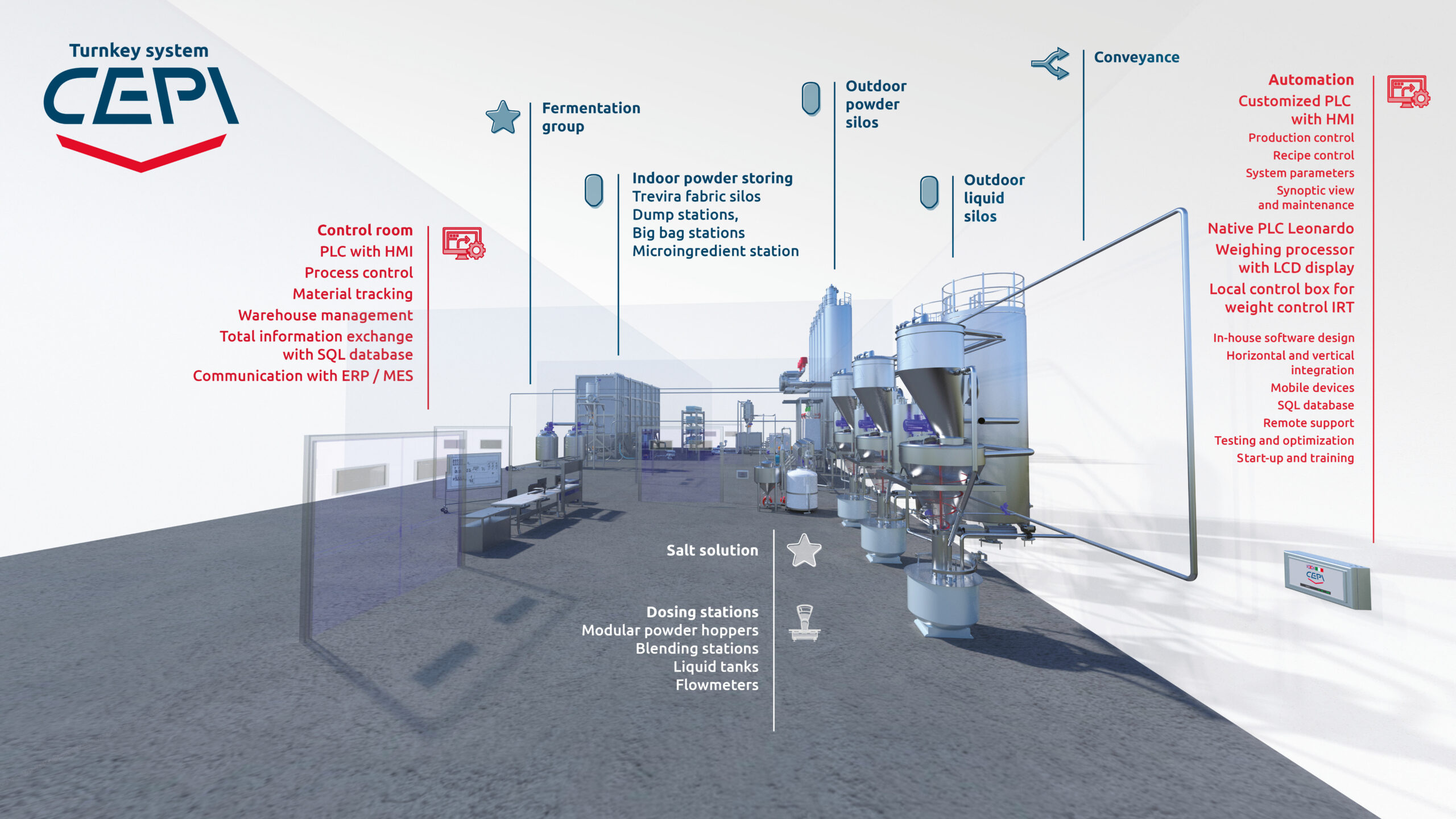

Our aim with is to create a virtuous circle in our research. With a dedicated space one idea will even more quickly lead to the other, in line with a vision that has always been centered around technology and customization. Our systems are turn-key, which has a deep meaning to us. From technological diversification to personalized innovation, from bulk-handling equipment to data, we aim to provide systems that can be managed in total independence once commissioning is done.

In our new testing room, our customers will be able to perform dosing and conveyance tests directly on their own materials. We also plan to develop system wide prototypes. With prototypes always available, we will be able to test an increasingly wider range of materials. The dosing of minor ingredients, for example, often includes new food products or mixes, and the impact of equipment on their characteristic is unknown, requiring tests in controlled conditions. This is the case of mixes for functional or nutraceuticals foods with or without gluten, or resins and pigments in the chemical sector. In the confectionery sector, it is important to test any product with a high fat percentage such as whole milk and powder butter.

Personalization and innovation are tightly connected to each other for us. Our research is often driven by the specific needs each food manufacturer brings to us: our latest dosing station 3IN1 (which combines weighing, blending and direct loading on the pneumatic line) has been developed in response to a customer’s need to optimize his productive area.

We are able to provide turn-key systems because our technological range is unparalleled. But in turn, our technological range is unparalleled because of our intense focus on customization. The same excellent synergy extends to the development of our data management systems.

Our new headquarters

What is a turn-key solution

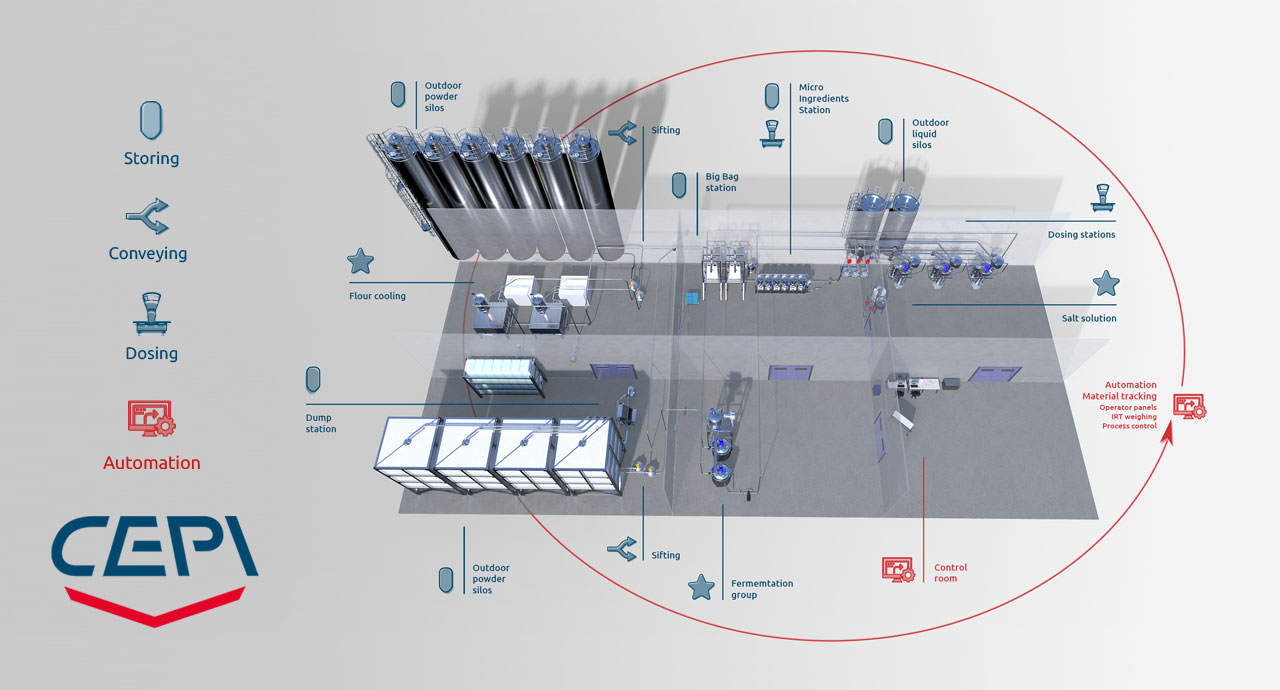

A turn-key solution is a solution that makes the user independent. What does this mean in practice? Firstly, the process needs to be covered from beginning to end, which in our case means storing to dosing. Secondly, the builder’s technological offer should be very diversified in order to support any materials and processes the user wishes to include, without the need to involve another supplier. Then, the builder needs to possess all expertise needed to design, build and commission the system. Last but not least, it is very important that the system provides the data related to its own operations. We feel that a system that is not able to do this cannot be called turn-key.

This is our working method. CEPI has been founded and has grown around the very idea of being turn-key provider.

The benefits for the customer are immediately clear. They are using a tailor-made installation that has been designed to meet their needs. We automatize and optimize their production, enabling their growth in a modular way without ever overturning their process. This means that a food manufacturer won’t have to adapt to a pre-made solution but rather the opposite happens.

Aside from the obvious considerations over reduced costs, working with a single provider also means interfacing with only one interlocutor, who will have complete knowledge of their system, and who has designed, built and commissioned it.

Every ingredient brings their own challenges. Fats, milk derivatives and creams require temperature management through storing and dosing, while dehumidified air must be used for hygroscopic materials such as sugar and salt require the use of dehumidified air. Viscous ingredients require specific transport and dosage methods. A turn-key partner like CEPI will be able to identify all such needs and provide the solutions required. Crucially, all these issues will be managed organically, coordinating complex processes in the most efficient way and producing data that is already integrated.

A system is only turn-key if it overlooks all aspects of the productive context it operates in. In our systems, the materials are managed and traced from the beginning to the end of the process. This not only allows extreme precision in the set-up of each operation (with management of aspects such as temperature and atmosphere), but also, we can constantly adjust them on the basis of the data.

In CEPI, we consider every installation unique. Each one has its own story. This is the heart of turn-key work: the dialogue and information exchange with the customer is always open, which creates growing opportunities for both of us. If the customer chooses it, CEPI can enter more deeply in their process and create an optimization proposal based on our experience. This is the case of a recent collaboration where we designed a more efficient dosing solution to include fruit and chocolate in a biscuit line, all without altering the authentic flavor of their product.

A turn-key system completes all operations and provides the related data

Turn-key: operations and data

A turn-key system is a system that manages all processes from storage to dosing. Because CEPI is able to do this for all materials, and additionally to track all ingredients and provide the data, we are able to offer an integrated and fully traceable system that enables food industry operators to always have production under control.

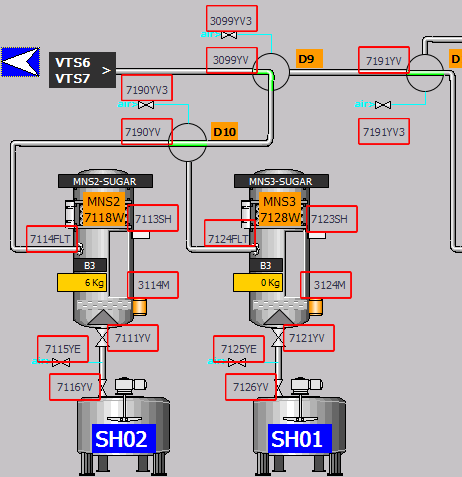

Our Tracking System software provides process control, warehouse management and full traceability with digitalization of all material movements. Our customers receive a complete picture of the production process in real time: we provide them with a history of storing and dosing operations, consumption statistics, batch report and related deviations, stock visualization and dynamic graphics illustrating all trends. Ingredients are monitored starting from the moment they enter the warehouse, carrying a virtual label through all production which adds new information every time an operation is performed on the ingredient.

All our data can be easily integrated with global ERP or MES to achieve organization-wide traceability. Our process control software is open, and the information is immediately available for the user, who can use it however they decide. Because we develop our software completely in-house, we are not bound to any third party and therefore our customers are not either.

Gathering, storing and making data on the materials available is crucial to a healthy process. It allows traceability and ensures food security, by knowing which ingredient lot from warehouse was dosed into each final unit, and makes it possible to verify the efficiency of a system.

On top of this, the data can be used in as many ways as the customer wants. They can quickly carry out mass production balances, check consumptions, generate information for Quality Control and Purchases, create projections of future productions and optimize the current process. Data on the tolerance and queue of dosing processes can be used to check the status of the equipment and determine if it requires maintenance.

We are currently working on ways to generate more process data for our customers, including alarm histories that can aid in planning personalized maintenance and solutions to historicize energy consumptions.

Tracking System: process control, traceability, warehouse management and total information exchange

Get a quote

Powders, granular products, liquids, fats. Macro, micro, medium volumes. Fermentation, flour cooling, fluidization, sugar milling, invert sugar, salt solution, blending, cold dosing, scrap rework. Our motto is: if your process needs it, we can do it. If we can’t do it yet, we will develop it, just for you.

Get a in touch to develop a fully customized and automated installation for your recipe: