Fabrizio Casetti joined CEPI in 2000. His experience began in the Technical Office as Manuals Specialist. Behind him, a diploma from the Marconi Institute in Forlì and the achievement of a degree in Electronic Engineering. Fabrizio Casetti has obtained specific training on manuals, following a course organized by the province (ENFAP / ECIPAR). Today, Fabrizio is Quality and Manuals Manager. Fabrizio follows refresher courses periodically, including within the company, and specific training and consultancy. He finds it stimulating in his work that it is never static, but constantly evolving and always improvable.

Fabrizio, can you explain what your office does?

Our office mainly deals with the drafting of manuals and technical documents intended for the user. Our final target is therefore the customer.

At the same time, we also carry out a quality control activity for products made within the company that require it for a regulatory issue. For example, the European ATEX directive, the machinery directive, food hygiene: all those mandatory certifications for machines that meet food substances.

Not only that: our office is also responsible for the drafting of documents and technical files. We create a real identity card for the machine, which tells about the project, moving on to the risk analysis, up to the certifications from notified bodies.

Our office interfaces mainly with two entities: on the one hand, the institutions, for issuing and updating certificates. On the other hand, with customers, for everything that concerns pre- and post-sales, regulatory and bureaucratic problems, requests for technical assistance for problems with operation, quality, compliance, regulations, starting procedures on site.

Who are your team members and what is their role?

I personally take care of organizing all the office activities, relying on a weekly updated work plan. At the beginning of the week, I assign specific tasks to each of my colleagues and then periodically check the progress of the work. To give you a more precise idea, my working method is inspired by ISO 9001: our processes and activities are based on the document management of this certification. Its organizational and structural approach pays off in terms of control, leaving no room for interpretations and ambiguities that can create confusion.

I also follow the technical drafting of new manuals and documentation of machines and mechanical and electromechanical equipment, plus articles and technical files. As responsible for certifications and, in particular, ATEX, I also check all those products that fall under this directive.

Not only that: all translation management is also my responsibility, I monitor the costs, because the documents we produce must be available in many foreign languages!

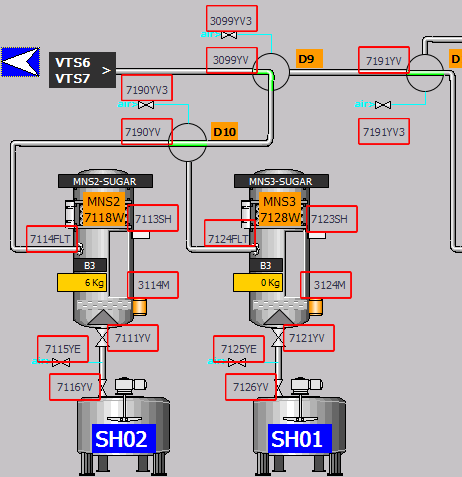

Estelle Inna Mbiekop, on the other hand, is responsible for drafting and checking the touch panel manuals.

Vania Nanni follows documents and manuals for each system, up to delivery to the customer.

Patrizio Caroli takes care of quality control on products before shipping and quality assistance support.

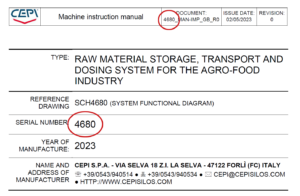

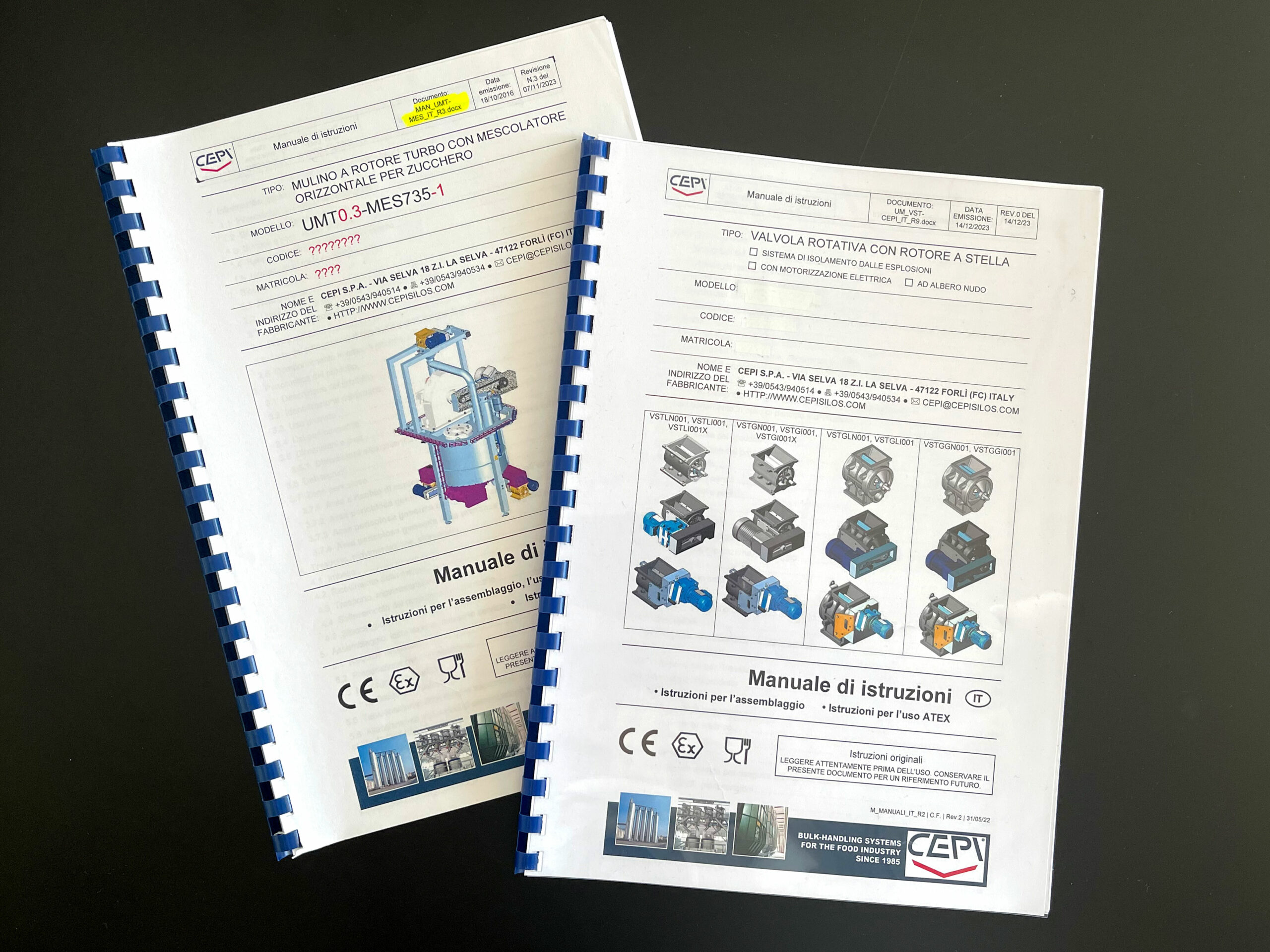

Instruction Manual for a CEPI system

What documents do you prepare and for whom?

We take care of drafting documents and procedures for internal use, such as instructions for construction sites, for example.

How do you ensure that all required documents are ready?

The most experienced staff are responsible for verifying the correctness of the documents before delivery. Our supplies are often subject to expansions and modifications; therefore, great attention and scrupulousness are required.

I have a little secret dream: I’d like to make a leap in quality and move on to more advanced technical drafting systems. I am already in contact with a technical studio that manages CMS for technical editing, and I hope it can be a good starting point for improvement.

You are a point of reference in CEPI for planning and procedure. What can you tell us about it?

Planning is the basis of our work. We use Excel logs to track and monitor delivery management and work progress, as well as create archives. In other words, we create procedures and work methods even if our systems are not automated.

For example, we give ourselves internal procedural rules on how to rename files, how to prepare and organize documents. It’s an orderly management of work that allows me to maintain control over the many activities I follow. I feel at ease with such order and method!

As I mentioned before, I would like the manual systems we work with to become automated one day, therefore moving on to software.

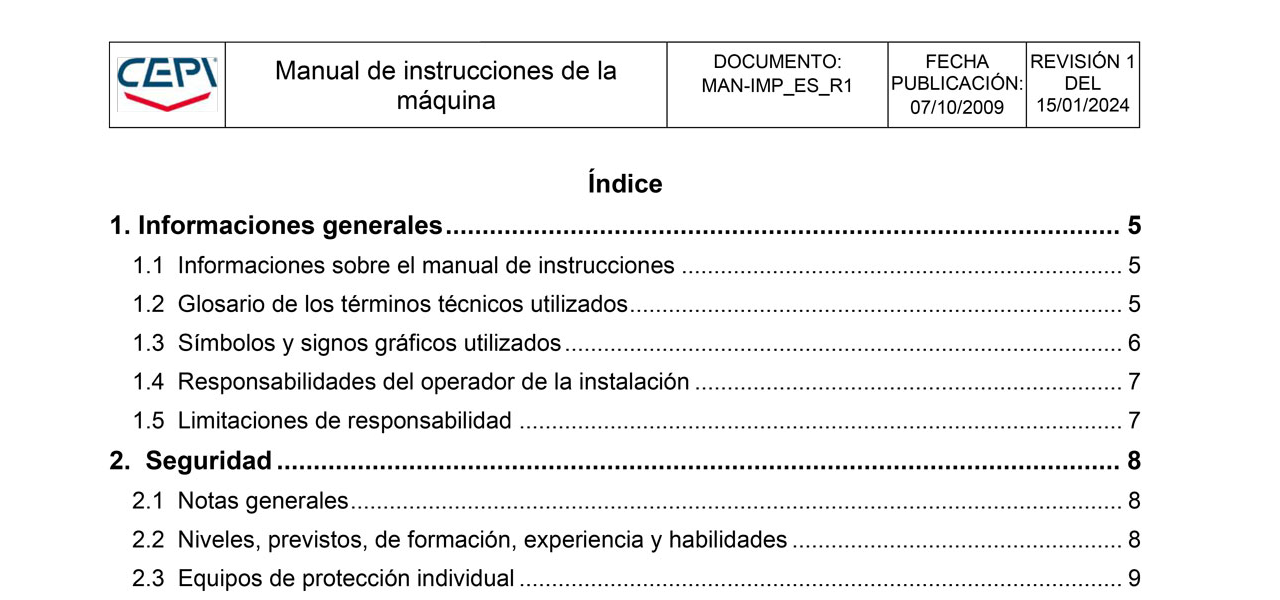

Estelle Inna Mbiekop and Vania Nanni at work

What do you think is important in managing a team?

Defining roles is essential. They must be very specific, with delineated boundaries. Everyone must know what they have to do and what their tasks are.

Another element in which I deeply believe is the continuous exchange between team members. Teamwork also consists of examining critical activities and, if necessary, redefining them.

Feedback and discussion are more than appreciated, they encourage dialogue and discussion, elements that are the basis of the work. The opinion of each of my colleagues matters and is never taken for granted.

Can you tell us a little about the manuals? How it is now in CEPI and how it has developed over the years.

Certainly, manuals have gone through a strong evolution, which on the one hand has been physiological because the amount of work has increased exponentially. I believe that this evolution is constant, I feel I still have a lot to learn. Over the years, procedures have improved and been speeded up.

On a quantitative level, the amount of work for each individual customer has increased greatly, both from the point of view of the complexity of the system and with regards to regulations: the requests have become more stringent, and the regulations have changed over the years. Our capabilities have also had to upgrade and must continue to do so constantly. In recent years we have, in fact, acquired many skills and knowledge in terms of manuals, regulatory and organizational aspects. Ours is continuous growth.

Regulations, legislation… what do these words evoke in you?

Our sector falls under a series of very complex and constantly evolving legal obligations. Always keeping up is essential. Regulations such as ATEX, the Machinery Directive – which is becoming a Regulation – and hygiene standards for products intended to meet food substances have a different weight depending on the country that requires them. We work with many countries around the world and for each territory it is necessary to know the legal obligations required for our production sector.

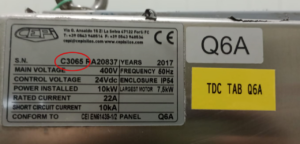

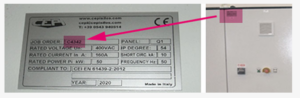

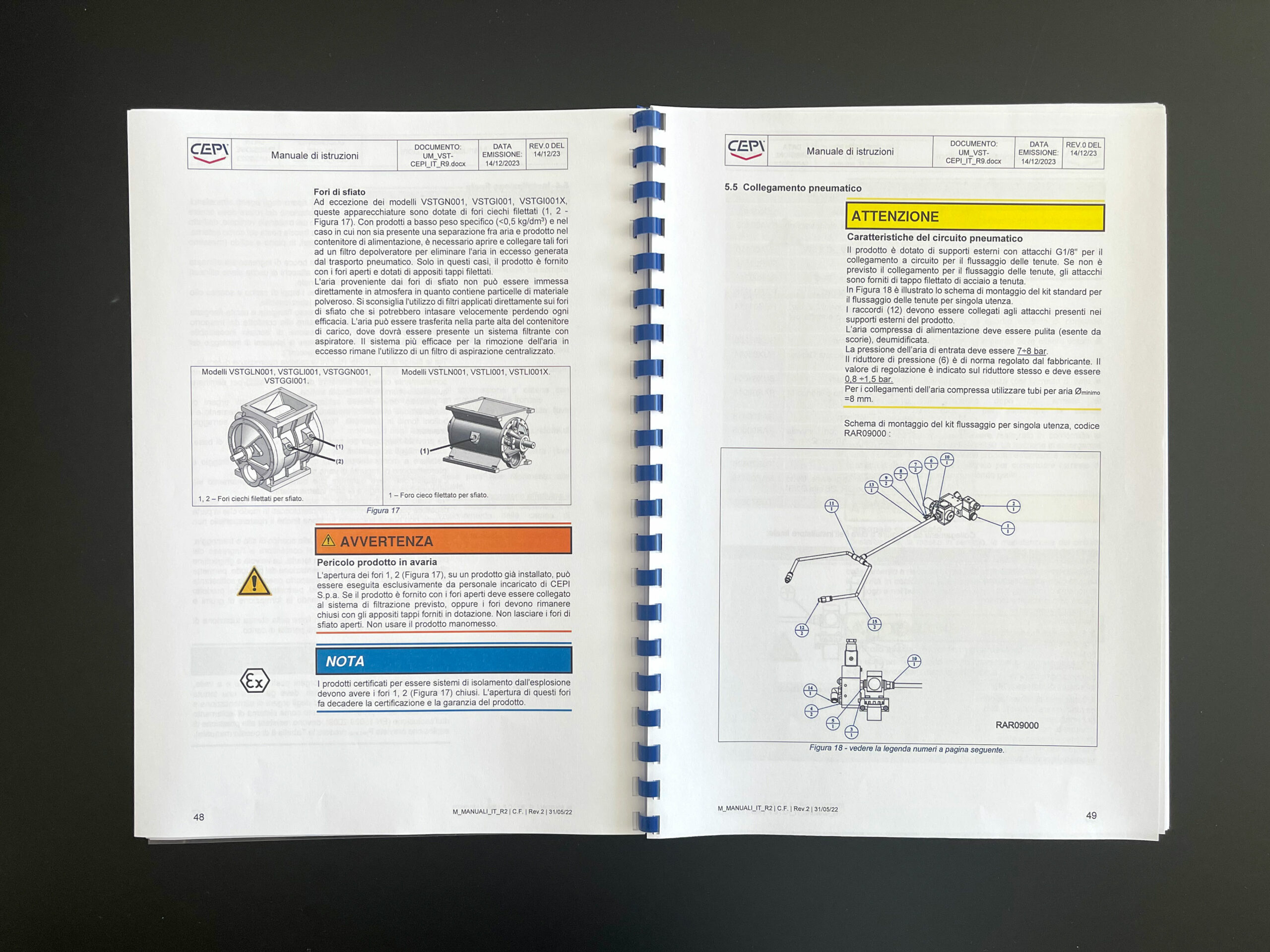

Technical documents for CEPI’s technologies

Technical document for CEPI’s rotary valve

CE marking, ATEX: which are the most important for customers?

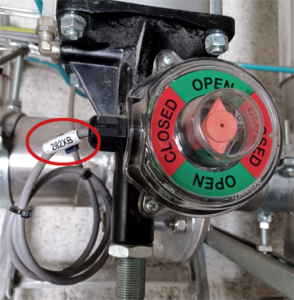

CEPI is sensitive and attentive to compliance with the legal requirements and regulatory standards applicable to its products (Machinery Directive, ATEX Directive, etc.). Over the years, the company has also obtained important product certifications, which constitute added value and have great attraction for customers. For example, the certification of its rotary valves with star rotor as explosion isolation systems (EN15089 – protection systems against the propagation of flame and explosion). Potentially, certifications regarding the supply of high-level components could be an interesting channel.

Bureaucracy: what does this word inspire you?

If you consider a management system just for the bureaucracy, then it’s not worth it. The goal is to create a more efficient way of working.

I believe that the presence of schemes to teach people to work using tools and schemes to reach a goal, without making mistakes, is a great added value.

However, it is important that the procedures are understood and that everyone works in a certain way; therefore, the transition from an artisanal to an industrial work system is presupposed.