Sustainability is becoming a key factor in food manufacturers’ decision-making. Reworking production scraps is good for the planet and for your production process, with less material consumptions and reduction of waste.

Scrap rework allows to recover faulty products rather than sending them for disposal. On top of reducing waste and achieving a more sustainable process, reworking scraps cuts both direct and indirect costs, as both disposal and material expenses are greatly lowered.

There are many other advantages to rework: recovering scraps helps achieving a more hygienic production, as the products are immediately reinserted into the production cycle, which ensures a higher food safety on the line as well. As well, rework optimizes space as both storage of product and waste is limited to the essential.

Rework can also hugely valorize scraps, as is the case of bread crumbs and croutons made from bread scraps. Rework is a very flexible process that allows for creating new recipes and intercepting other markets (as is the case of crumbs and croutons), but also support current production with uses such as sourdough production.

CEPI is proud to offer automated rework systems for bread and similar products, as well as both dry and liquid biscuit rework. Our systems are customized and adaptable: the level of breakage and any other details are chosen by the customer – covering in cakes usually requires crushing, whereas the product is pulverized to go back into the dough or inside spreadable creams.

Some companies choose to use their scraps for the same product while some create a completely new recipe. Some use their bread scraps to as fermentation base in the sourdough, some bring it back almost to flour to reuse it to make, for example, tortillas. As is our habit, we adjust our design to the customer’s project, offering food technology and recipe support during development.

As per our standard, both bread and biscuit rework systems are developed to fully preserve food properties. Our processes guarantee a high quality end product with no loss of proteins compared with the flour used in the beginning of the process.

Our technology supports the production of a completely new recipe or more of the same product

Bread rework

Our bread rework system is fully automated and traceable, and can be used not only for bread but also similar products, such as toasts, loaves and sandwiches. Its final product can be fed back into production in place of flour or worked again to produce new recipes such as croutons or bread crumbs. It can also be sold or used for animal feed.

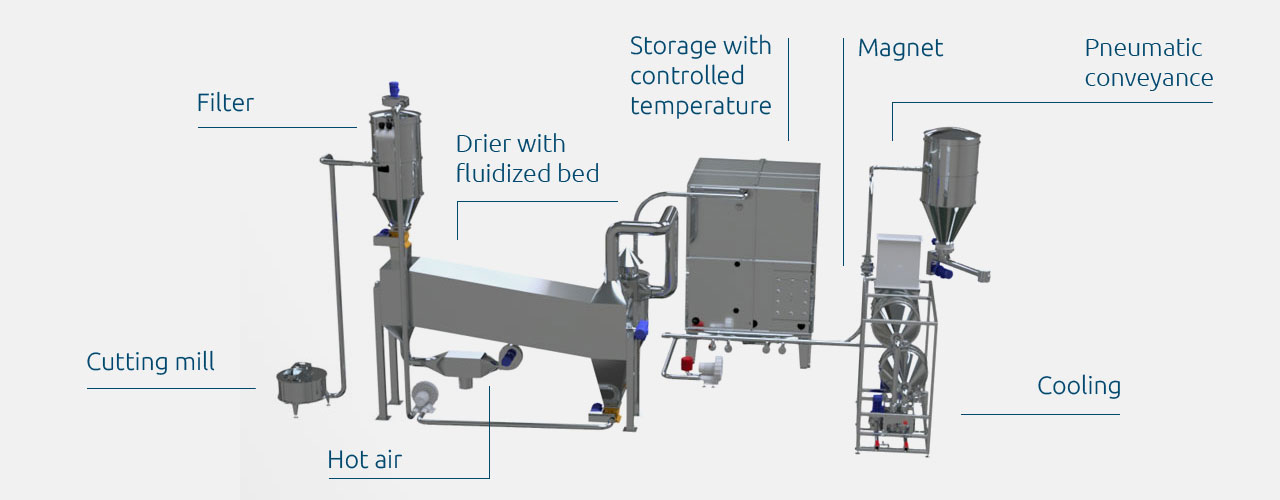

The system includes loading, drying, cooling, grinding and storing with temperature control as well as pneumatic conveyance.

The process begins with scraps being ground in a cutting mill (placed at ground level to facilitate loading). Loading can be done both manually from the sacks, or directly from the line, and also from different locations through the conveyor belts. The product is then transferred by vacuum to a hot-air dryer with fluidised bed and filter. During this phase the product acquires all necessary features for the various applications it is being recovered for.

After this the product is sent through pneumatical transport in a stainless steel silo with fluidized bed, for storage with controlled temperature. The product can be worked into bread crumbs by adding a hammer mill in the installation, or crouton by using an extruder.

Biscuit rework: dry and liquid

The dry rework of biscuit scrap re-uses the powders on the production line. The system includes loading, grinding and storing with temperature control as well as pneumatic conveyance, with cutting mill, magnet and filter. All equipment in stainless steel and weight control in real time, integrated automation and full traceability.

We have recently launched a technology for the liquid recovery of sandwich biscuit. Sandwich biscuit scraps are broken inside a stainless steel tank with stirrer that creates an emulsion with a liquid part (oil, fat or water) to be dosed directly on mixer to produce more biscuits.

The system consists of a hopper for the dosing of oil or water, manual loading of biscuit scraps, breaking and production of emulsion inside the tank, conveyance to liquid hopper and dosing on mixer. The tank can be heated or double-jacketed depending on the process and is completely automated with PLC and HMI screen.

Our biscuit rework systems ensure high levels of hygiene with total emptying in the recovery tank. The tank is designed specifically for the management of rework materials, with rounded design and impeller to crush, homogenize and then be completely unload the product. Each system can also be equipped with CIP washing system for the total hygienization of tanks and pipes.

Sandwich biscuit rework

Learn more and get a quote

Learn more about dry bread and biscuit rework → cepisilos.com/special-application/rework

Learn more about sandwich biscuit rework → cepisilos.com/special-application/sandwich-biscuit-rework

Powders, granular products, liquids, fats. Macro, micro, medium volumes. Fermentation, flour cooling, fluidization, sugar milling, invert sugar, salt solution, blending, cold dosing, scrap rework. Our motto is: if your process needs it, we can do it. If we can’t do it yet, we will develop it, just for you.

Get a in touch to develop a fully customized and automated installation for your recipe: