Health and wellness are currently among the most powerful drivers in any market. Consumer attitudes toward food are shifting, as people increasingly seek products that can provide benefits beyond nutrition. The industries for naturally healthy food, functional food and enriched foods have experienced some of the fastest growth globally in the last few years.

Cereal bars are one of the most sought-after products among such health conscious consumers. But it does not end there: because of their tastiness, nutritional value and easiness of consumption, they are also incredibly popular with the general public.

Consumed as breakfast, snacks, meal substitutes, or as energy and performance bars, cereal bars have become a highly diversified product. Single or multi-layer, they are produced with complex recipes that involve multiple cereal ingredients, dry-grain, nuts and seeds, and additions like chocolate, honey, caramel, dry fruit, proteins and mineral salts.

The dosing system into a cereal bar line must provide accuracy, homogeneity and avoid intrusive processing. It must be designed to meet the individual requirements of each recipe, improve process efficiency and protect the unique flavour of the final product. As direct manufacturers with a vision prioritizing research, flexibility and customization, CEPI is perfectly positioned to meet such needs. Our installations are completely automated, and we bring vaste food technology expertise and an unparalleled technological range to each project.

The CEPI system

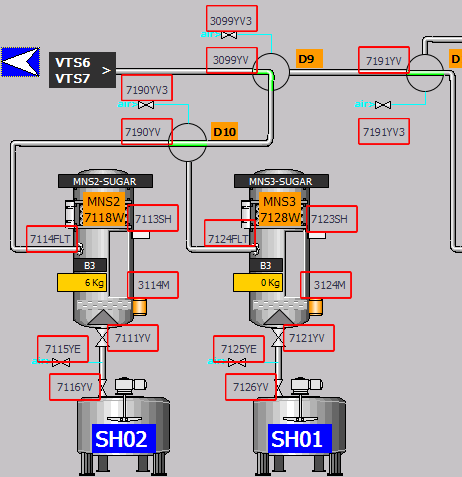

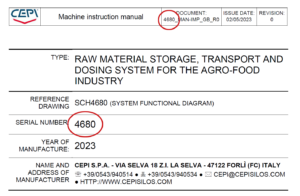

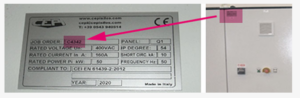

The CEPI system provides continuous dosing into the line and comes with multiple ingredient storage, output with multiple vibratory feeders and control panel with HMI screen. The ingredients are dosed in parallel toward the binder according to the ratio required by the recipe. You can find out about the layout and flow of the dosing system in the product sheet.

Our system delivers precision and accuracy, ensures the even spread of raw ingredients and a homogenous composition in each bar. The process respects the properties of the ingredients and includes integrated automation and full traceability.

Easy maintenance and cleaning.

To discuss your project and get a quote, get in touch at cepi@cepisilos.com. We are eager to build the best solution for your recipe.